Professional Backyard Putting Green Construction | Artificial Turf

Aug . 09, 2025 04:40 Back to list

The pursuit of leisure and personal amenities at home has led to a significant surge in demand for bespoke outdoor living spaces. Among these, the integration of a private putting green stands out as a luxurious yet practical addition, offering both recreational value and a serene aesthetic. This comprehensive guide delves into the intricate world of backyard putting green construction, exploring the cutting-edge techniques, superior materials, and strategic advantages that make artificial turf the preferred choice for discerning homeowners and commercial developers alike. We will illuminate the industry's evolving landscape, provide granular technical insights, and showcase the unparalleled benefits of adopting advanced artificial grass solutions.

The Evolution of Residential Golf: Why Artificial Putting Greens Are Redefining Backyards

The landscape of home entertainment and outdoor leisure has undergone a transformative shift. No longer just a luxury confined to golf clubs, the dream of having a dedicated putting space at home is now an accessible reality. This trend is driven by a confluence of factors: a desire for convenience, the pursuit of year-round playability, and an increasing awareness of environmental sustainability. Traditional grass putting greens demand substantial resources—water, fertilizers, pesticides, and constant maintenance. In contrast, modern artificial putting greens offer a compelling alternative, providing a pristine, consistent surface with minimal upkeep, making them ideal for modern lifestyles.

Industry Trends and Driving Forces

The market for backyard putting green construction is experiencing robust growth, propelled by several key trends:

- Sustainability and Water Conservation: With increasing concerns over water scarcity and environmental impact, artificial turf solutions are highly attractive. A typical natural grass putting green can consume thousands of gallons of water annually. Artificial turf requires no irrigation, significantly reducing water footprints.

- Low Maintenance Appeal: Homeowners are seeking low-effort solutions that free up time. Artificial greens eliminate the need for mowing, fertilizing, weeding, and pest control, offering a truly "set it and forget it" experience for consistent play.

- Year-Round Playability: Unlike natural grass, which can be affected by weather conditions (drought, heavy rain, frost), artificial putting greens remain playable regardless of the season, providing a reliable practice surface all year.

- Customization and Aesthetic Integration: Advanced artificial turf technologies allow for highly customizable designs, seamlessly integrating putting greens into existing landscape architecture, from intricate contours and multi-hole designs to realistic fringe and chipping areas.

- Increased Property Value: A professionally installed, high-quality artificial putting green can be a significant selling point, adding both functional value and aesthetic appeal to a property.

Technical Parameters and Material Excellence in Artificial Putting Greens

The quality and performance of an artificial putting green are fundamentally determined by its technical specifications and the materials used. Understanding these parameters is crucial for ensuring a durable, realistic, and high-performing surface. Our product, Artificial Grass for Construction Sites, is designed with these rigorous standards in mind, offering exceptional resilience and realistic play characteristics suitable for any backyard putting green construction project.

Key Technical Specifications and Their Impact

When selecting materials for an backyard putting green construction, several critical parameters come into play:

- Fiber Material: Primarily Polyethylene (PE) or Polypropylene (PP), sometimes Nylon blends. PE offers a soft, realistic feel and excellent durability, making it ideal for putting surfaces. PP is often used for fringe or rough areas due to its stiffer nature. Nylon provides superior resilience and memory but is typically more expensive. Our product utilizes high-grade PE fibers, engineered for optimal ball roll and putting consistency.

- Pile Height (mm): This refers to the length of the individual grass blades. For putting greens, pile heights typically range from 10mm to 25mm (0.4 to 1 inch). Shorter pile heights (10-15mm) provide faster ball roll, mimicking a tournament-grade green. Slightly longer heights (18-25mm) offer a slightly slower, more forgiving roll, akin to a public course.

- Face Weight (oz/sq yd): Measures the total weight of the yarn per square yard, excluding the backing. Higher face weights generally indicate a denser, more durable turf. For putting greens, face weights can range from 40 oz to 60 oz, influencing the resilience and infill requirements.

- Stitch Rate (stitches/10cm): The number of stitches per 10 centimeters (or inches) along the tufting line. A higher stitch rate means a denser turf, which is crucial for the consistent ball roll required on a putting green.

- Tufting Gauge (inches): The distance between rows of stitches. Common gauges for putting greens are 3/8 inch or 5/8 inch. A smaller gauge contributes to higher density.

- Backing Material: Crucial for turf stability, dimensional stability, and drainage. Common backing materials include SBR Latex and Polyurethane. Polyurethane backing offers superior dimensional stability, tear strength, and resistance to expansion/contraction from temperature changes, as well as excellent drainage characteristics. Our Artificial Grass for Construction Sites leverages robust backing systems to ensure longevity and optimal performance.

- Infill Material: Applied after installation, infill (typically silica sand or specialized crumb rubber/acrylic-coated sand) helps the blades stand upright, provides ballast, protects the backing from UV degradation, and impacts ball roll speed. The type and amount of infill are critical for customizing green speed.

Product Spotlight: Artificial Grass for Construction Sites

While the name suggests industrial applications, our Artificial Grass for Construction Sites (Product URL: https://www.hoyarngrass.com/artificial-grass-for-construction-sites.html) is an exceptionally versatile and durable product. Its robust construction, designed to withstand challenging environments, makes it an ideal choice for high-performance backyard putting green construction. The product’s superior wear resistance, UV stability, and excellent drainage properties ensure it can provide a consistent and aesthetically pleasing putting surface for many years. It is particularly suited for areas requiring extreme durability and minimal maintenance, perfectly aligning with the demands of a residential or commercial putting green.

Comprehensive Process Flow for Backyard Putting Green Construction

The successful installation of a backyard putting green construction project is a multi-step process that demands precision, expertise, and adherence to best practices. From the initial design phase to the final infill, each step contributes to the overall performance, longevity, and aesthetic appeal of the green. Below is a detailed breakdown of the typical manufacturing and installation process, highlighting key stages and considerations.

Manufacturing Process of Artificial Grass (General Overview - analogous to "Casting, Forging" for metals)

The creation of high-quality artificial grass, such as our Artificial Grass for Construction Sites, involves sophisticated manufacturing processes to ensure durability and realism.

- Yarn Extrusion: High-grade polymers (Polyethylene, Polypropylene) are melted and extruded through a dye to form individual fibers. These fibers are then twisted or textured to create specific blade shapes (e.g., C-shape, V-shape, S-shape) that enhance resilience, reduce glare, and improve realism. This stage is analogous to material preparation in traditional manufacturing.

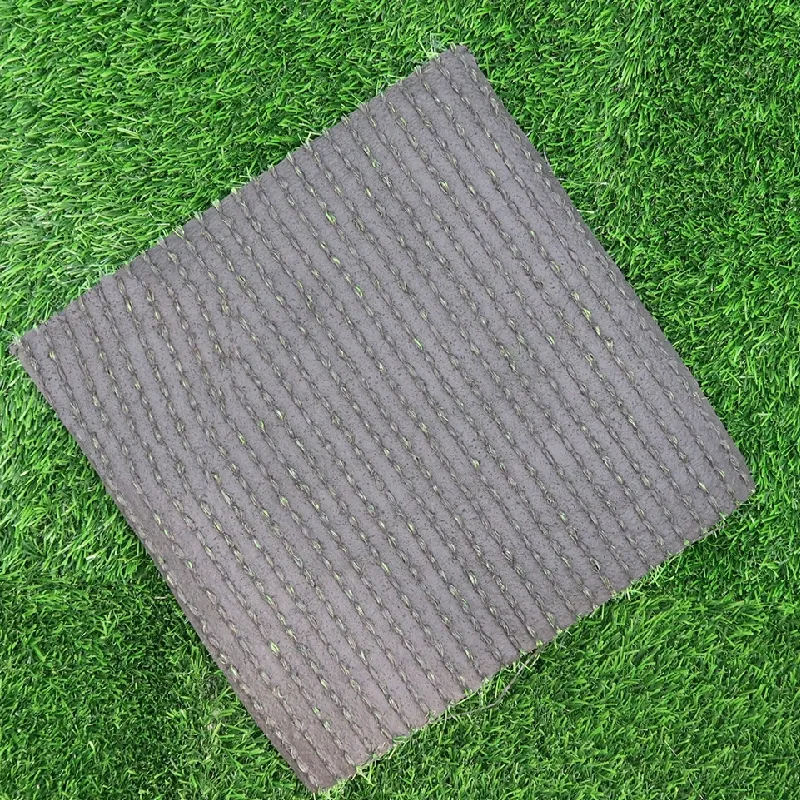

- Tufting: The extruded yarn is then spooled and fed into a large tufting machine. Needles punch the yarn through a primary backing fabric (typically woven polypropylene) in precise rows, creating loops. A "looper" mechanism then cuts these loops to form the characteristic "grass" blades. This process is similar to weaving or intricate assembly in other industries.

- Coating (Backing Application): Once tufted, the primary backing with the attached fibers moves to a coating line. A layer of secondary backing material, usually SBR Latex or Polyurethane, is applied to the reverse side. This coating firmly locks the fibers in place, prevents shedding, and provides dimensional stability. Polyurethane coatings, utilized in our premium products, offer superior bonding strength and excellent drainage. This step can be compared to a bonding or finishing process in other manufacturing sectors.

- Drying and Curing: The coated turf undergoes a drying and curing process, often in large ovens, to ensure the backing material is fully set and bonded.

- Perforation (Drainage Holes): For putting greens and landscape applications, drainage holes are typically punched into the backing at regular intervals to allow water to permeate through the turf.

- Quality Control and Inspection: Throughout the entire manufacturing process, rigorous quality control checks are performed. This includes testing fiber strength, UV stability, tuft bind (how well fibers are held in the backing), tear strength, and dimensional stability. Our products adhere to international standards such as ISO 9001 for quality management and ASTM (American Society for Testing and Materials) standards for performance and safety.

- Cutting and Packaging: The finished turf rolls are cut to standard or custom lengths and then packaged for shipment.

Installation Process of a Backyard Putting Green (Site-Specific Application)

Here's a detailed process for backyard putting green construction, often involving schematic diagram elements:

图解: Backyard Putting Green Construction Flow Diagram

Planning & Design ➡️ Site Preparation & Excavation ➡️ Drainage System Installation ➡️ Base Layer Installation & Compaction ➡️ Edging Installation ➡️ Weed Barrier (Optional) ➡️ Artificial Turf Laying & Seaming ➡️ Infill Application ➡️ Final Brushing & Grooming ➡️ Cup & Flagstick Installation

Phase 1: Planning and Design

- Site Assessment: Evaluate the chosen area for size, sun exposure, existing topography, and drainage patterns. Identify any obstacles or unique features.

- Design & Layout: Work with a designer (or plan yourself) to determine the shape, size, number of holes, contours, breaks, and fringe areas. Consider ball roll speed (Stimp rating) and desired challenges.

Phase 2: Site Preparation and Excavation

- Marking Out: Accurately mark the perimeter of the putting green based on the design.

- Excavation: Excavate the area to a depth of 4-6 inches (10-15 cm). This depth is crucial for accommodating the base layers and ensuring proper drainage. Remove all organic matter, rocks, and debris.

Phase 3: Drainage System Installation (Crucial for longevity)

- Sub-Base Grading: Ensure the excavated area is properly sloped (typically 1-2% grade) to facilitate water runoff towards a designated drainage point. This prevents water pooling.

- Drainage Fabric (Optional but Recommended): Lay a permeable geotextile fabric at the bottom of the excavated area. This helps prevent the base material from mixing with the native soil and improves drainage.

Phase 4: Base Layer Installation and Compaction

- Crushed Aggregate Base: Apply a layer of crushed aggregate (e.g., decomposed granite, crushed limestone, or granite fines) typically 3-4 inches (7.5-10 cm) thick. This material compacts well, provides a stable foundation, and allows for excellent drainage.

- Shaping & Contouring: Carefully shape the aggregate base to create desired undulations, breaks, and slopes of the putting green. This is where the green's character truly takes form.

- Compaction: Thoroughly compact the base layer using a vibratory plate compactor. Achieve a compaction rate of at least 90-95% to ensure a stable, unyielding surface that will not settle over time. Multiple lifts and compaction passes may be needed.

- Fines Layer: Some installers add a thin (1/2 inch) layer of finer crushed aggregate on top of the main base for a smoother, more precise surface.

Phase 5: Edging Installation

- Perimeter Edging: Install a durable edging material (e.g., bender board, flexible plastic edging, or concrete curb) around the perimeter of the putting green. This defines the shape, contains the infill, and provides a clean transition to surrounding landscaping.

Phase 6: Weed Barrier (Optional but Recommended)

- Geotextile Fabric: Lay a permeable weed barrier fabric over the compacted base. This adds an extra layer of protection against weed growth from below and further stabilizes the base.

Phase 7: Artificial Turf Laying and Seaming

- Unrolling and Acclimation: Unroll the artificial turf (e.g., our Artificial Grass for Construction Sites) over the prepared base. Allow it to acclimate to the ambient temperature for a few hours to minimize wrinkles or creases.

- Trimming: Carefully trim the turf to fit the exact shape of the green, ensuring clean edges.

- Seaming: For larger greens requiring multiple turf pieces, seams are crucial. Lay seam tape (a non-woven fabric) beneath the joining edges. Apply specialized turf adhesive to the tape, then carefully press the turf edges together, ensuring the pile direction is consistent for a seamless look and uniform ball roll. Use a seaming tool or roller to ensure a strong bond.

- Securing the Edges: Secure the perimeter of the turf using galvanized nails or staples, typically every 6-12 inches (15-30 cm) along the edges, ensuring they are flush with the turf surface.

Phase 8: Infill Application

- Spreading Infill: Evenly spread the chosen infill material (e.g., silica sand, specific putting green infill) over the turf surface using a drop spreader.

- Brushing Infill: Use a power broom or a stiff-bristled push broom to work the infill deep into the turf fibers. This helps the blades stand upright, provides stability, and crucially affects the speed of the ball roll. Multiple applications and brushing sessions may be required to achieve the desired Stimp rating.

Phase 9: Final Brushing and Grooming

- Final Grooming: Give the entire green a final brush to ensure all fibers are standing erect and the infill is evenly distributed. This enhances the aesthetic appeal and ensures consistent playability.

Phase 10: Cup and Flagstick Installation

- Cup Placement: Precisely cut holes for the putting cups using a specialized turf cutter.

- Cup Installation: Install the putting cups flush with the turf surface, ensuring they are securely anchored.

- Flagstick Installation: Insert flagsticks into the cups.

This meticulous process ensures that the backyard putting green construction results in a high-performance, long-lasting, and visually stunning golfing amenity.

Application Scenarios and Strategic Advantages

The versatility and performance of artificial putting greens, particularly those constructed with durable products like Artificial Grass for Construction Sites, extend beyond simple residential backyards. Their robust nature and low maintenance make them suitable for a wide array of applications, each benefiting from their unique technical advantages.

Diverse Application Scenarios

- Residential Backyards: The most common application, providing homeowners with a convenient and accessible space to practice their short game, entertain guests, and enhance their property's aesthetic and recreational value.

- Commercial Properties: Hotels, resorts, luxury apartment complexes, and corporate campuses are increasingly installing artificial putting greens as amenities to attract and retain clients, offering a unique recreational outlet.

- Golf Clubs and Driving Ranges: While traditional courses use natural grass, artificial turf is ideal for chipping areas, practice greens, and even tee lines at driving ranges, providing consistent performance and reducing maintenance in high-traffic zones.

- Schools and Universities: Educational institutions can integrate putting greens into sports facilities or landscape designs, offering students opportunities for golf practice or general recreation.

- Indoor Golf Simulators: Artificial turf provides the ideal surface for indoor golf training facilities, offering consistent ball roll and excellent durability for repeated use.

- Miniature Golf Courses: The flexibility in design and low maintenance of artificial turf make it perfect for commercial or private mini-golf courses.

Technical Advantages and Performance Benefits

The selection of premium artificial grass for backyard putting green construction offers a compelling array of advantages over natural grass:

- Unrivaled Durability and Longevity: Engineered with UV-stabilized fibers and robust backing, artificial putting greens can withstand harsh weather conditions, heavy foot traffic, and prolonged sun exposure without fading, degrading, or losing performance. Products like our Artificial Grass for Construction Sites are built to last 15-20 years or more, offering significant return on investment.

- Consistent Ball Roll and Speed: Precision manufacturing and controlled infill application allow for a highly consistent and predictable ball roll, mimicking the performance of a professional-grade natural green. The Stimp meter reading (a measure of green speed) can be precisely adjusted during installation.

- Exceptional Drainage: With permeable backing and proper base preparation, artificial greens drain water efficiently, preventing puddling and allowing for immediate play after rain. This is a critical advantage over natural greens, which can become waterlogged and unplayable.

- Aesthetic Appeal Year-Round: Artificial turf maintains its vibrant green color and manicured appearance throughout the year, irrespective of seasons, droughts, or extreme temperatures. It requires no divot repair, ensuring a perpetually perfect look.

- Eco-Friendly Attributes: Beyond water conservation, artificial greens eliminate the need for chemical fertilizers, herbicides, and pesticides, reducing chemical runoff and contributing to a healthier environment. They also reduce carbon emissions associated with mowing.

- Pest and Disease Resistance: Unlike natural grass, artificial turf is impervious to common lawn pests (e.g., grubs, armyworms) and fungal diseases, eliminating the need for costly and environmentally questionable chemical treatments.

- Child and Pet Friendly: A clean, non-toxic, and allergen-free surface makes it safer for families and pets. There are no mud patches, no grass stains, and fewer allergens like pollen.

Manufacturer Comparison and Customization Solutions

Navigating the market for backyard putting green construction requires a discerning eye, as not all artificial turf products are created equal. Choosing the right manufacturer and understanding the scope of customization available are paramount to achieving a truly exceptional putting green.

Key Factors in Manufacturer Comparison

When evaluating manufacturers or suppliers for your artificial turf needs, consider the following critical aspects to ensure quality, reliability, and support:

- Product Quality and Material Sourcing: Investigate the quality of the yarn (e.g., virgin polymer vs. recycled, UV stabilization, denier) and the backing material. Reputable manufacturers, like us, use high-grade, non-toxic materials designed for longevity and performance, meeting international standards such as ISO 9001 (Quality Management Systems) and ASTM (American Society for Testing and Materials) for various performance metrics.

- Manufacturing Processes: Understand their manufacturing rigor. Do they employ advanced tufting and coating technologies? Is their quality control stringent? For example, products like Artificial Grass for Construction Sites are produced using state-of-the-art machinery and processes, ensuring consistent quality.

- Certifications and Standards: Look for certifications from reputable bodies. For instance, turf products should meet specific lead-free standards (e.g., Prop 65 compliance), and manufacturing facilities should be ISO certified. Testing for UV degradation, heavy metals, and flammability is also important.

- Warranty and Lifespan: A strong warranty (typically 8-15 years) indicates a manufacturer's confidence in their product's durability. Inquire about projected lifespan under typical usage conditions. Our products are designed for long-term performance, often exceeding standard warranty periods.

- Customer Support and Technical Assistance: A good manufacturer provides comprehensive pre-sale consultation, technical data sheets, installation guides, and responsive post-sale support. This is crucial for successful project execution, especially for complex backyard putting green construction.

- Industry Reputation and Experience: How long has the company been in business? What are their client testimonials and case studies like? A long track record of successful projects and positive client feedback speaks volumes about their reliability and expertise.

Tailored Customization Solutions

One of the most compelling aspects of artificial putting greens is the ability to fully customize their design and performance. Manufacturers and installers collaborate with clients to create a putting green that perfectly fits their vision, space, and skill level.

- Shape and Size Flexibility: Unlike traditional greens limited by site conditions, artificial turf can be cut and shaped to virtually any dimension or artistic design, from free-form organic shapes to highly geometric patterns. This allows for seamless integration into diverse landscapes.

- Contour and Undulation: The base layer can be precisely sculpted to incorporate subtle breaks, challenging undulations, and elevation changes, mimicking the complexity of championship courses. This requires skilled base preparation.

- Number and Placement of Holes: Clients can choose the number of cups and their strategic placement to create varied putting lines and challenges, catering to different skill levels or practice routines.

- Fringe and Chipping Areas: Integrate slightly longer pile artificial grass (often 30-50mm) around the putting surface to simulate the rough or fringe of a golf course, allowing for realistic chipping practice.

- Green Speed Customization (Stimp Rating): Through the selection of specific turf types (pile height, density) and the precise application and brushing of infill, the speed of the green can be calibrated to a desired Stimp rating, from slower home greens to faster professional-level surfaces.

- Bunkers and Water Features: For more elaborate designs, artificial turf can be combined with sand traps (bunkers) or even integrated water features, enhancing both the challenge and the aesthetic appeal.

- Lighting and Landscaping: Incorporate landscape lighting for evening play or surrounding landscaping elements (plants, rocks, paving) to enhance the overall beauty and functionality of the area.

Our commitment to providing tailored solutions ensures that every backyard putting green construction project, regardless of its scale or complexity, is executed to the highest standards, delivering a personalized and high-performance outcome.

Real-World Application Cases and Performance Metrics

The efficacy and versatility of artificial putting greens are best illustrated through their successful implementation across various settings. These case studies highlight not only the aesthetic transformation but also the measurable performance benefits derived from high-quality backyard putting green construction using products like Artificial Grass for Construction Sites.

Case Study 1: Suburban Residential Oasis

Client: Private homeowner in a drought-prone region.

Challenge: Desired a personal putting green but faced strict water restrictions and high maintenance costs for natural grass. Needed a consistent surface for daily practice.

Solution: Installed a 700 sq ft (approx. 65 sqm) custom-designed artificial putting green with a moderate Stimp speed (around 9-10). The design included two cups, subtle breaks, and a fringe chipping area using our Artificial Grass for Construction Sites due to its durability and realistic short pile. The project was completed in 4 days.

Results: The client reported a 90% reduction in water usage for that section of their yard and virtually eliminated landscape maintenance related to the green. The consistent ball roll allowed for significant improvement in their short game, and the green remained vibrant and playable through all seasons, even during extreme heat waves. Customer feedback highlighted the "transformative impact on their leisure time and golf skills."

Case Study 2: Boutique Hotel Amenity Upgrade

Client: Luxury boutique hotel seeking to enhance guest experience.

Challenge: Wanted to add a unique outdoor amenity for guests but had limited space and budget for ongoing landscape maintenance. Required a visually appealing, low-upkeep solution.

Solution: A 1200 sq ft (approx. 111 sqm) multi-hole artificial putting green was designed and installed in a previously unused courtyard area. The design incorporated architectural elements of the hotel, creating a cohesive and inviting space. The chosen turf (our Artificial Grass for Construction Sites for its high-traffic resilience) offered a slightly slower, more forgiving roll, appealing to a broader range of guest skill levels.

Results: The putting green became a popular guest attraction, generating positive reviews and increasing guest satisfaction. Hotel management reported a negligible increase in maintenance costs for the area, and the green maintained its pristine appearance, contributing to the hotel's luxury ambiance. This demonstrated the product's superior performance in a commercial, high-traffic environment.

Performance Metrics and Data-Driven Insights

To further illustrate the advantages, here's a comparison of key parameters often considered in backyard putting green construction:

| Parameter | Description | Optimal Range / Specification | Impact on Performance |

|---|---|---|---|

| Pile Height (Putting) | Length of grass blades on the putting surface. | 12-20 mm (0.5-0.8 inches) | Shorter piles give faster ball roll (higher Stimp), longer piles offer more forgiveness. Our product excels here. |

| Face Weight | Density of the turf fibers (yarn weight per square yard). | 40-60 oz/sq yd (1350-2030 g/m²) | Higher face weight indicates denser turf, better durability, and consistent surface. |

| Stitch Rate | Number of stitches per unit length (e.g., 10 cm). | 28-36 stitches/10cm (typical for putting greens) | Higher stitch rate means denser turf, crucial for true ball roll and appearance. |

| Backing Material | Material on the reverse side of the turf that holds fibers. | Polyurethane (PU) preferred over SBR Latex | PU offers superior dimensional stability, tear strength, and excellent drainage, especially relevant for our Artificial Grass for Construction Sites. |

| Infill Type & Amount | Granular material brushed into the turf for stability and performance. | Silica Sand (Round, kiln-dried) or specialized putting green infill; 2-4 lbs/sq ft | Determines ball roll speed (Stimp), protects fibers, provides ballast. Critical for custom green speed. |

| Base Material Depth | Thickness of the compacted aggregate base. | 3-4 inches (7.5-10 cm) of compacted aggregate (e.g., decomposed granite) | Ensures stability, proper drainage, and allows for shaping contours. Essential for avoiding settling. |

| Drainage Rate | How quickly water passes through the turf and base. | Typically > 30 inches per hour (via turf backing and permeable base) | Prevents waterlogging, allows for immediate play after rain, critical for longevity. |

| UV Stability | Resistance of fibers to degradation from sunlight. | ASTM G155-Cycle 1 or higher; > 5,000 hours without significant fading/degradation | Ensures long-term color retention and structural integrity, preventing premature aging. |

These detailed parameters and case examples underscore the technological advancements and practical benefits of choosing high-quality artificial turf for any backyard putting green construction project, ensuring both performance and enduring value.

Enhancing Trust: Our Commitment to Quality and Support

At the core of every successful backyard putting green construction lies a foundation of trust. Our company, with years of experience in the artificial turf industry, is dedicated to providing not only superior products like Artificial Grass for Construction Sites but also comprehensive support and unwavering reliability, adhering to the highest standards of Authoritativeness and Trustworthiness.

Industry Certifications and Authority

Our commitment to excellence is validated by adherence to stringent international standards and partnerships with leading industry bodies:

- ISO 9001 Certified Manufacturing: Our production facilities operate under ISO 9001 Quality Management Systems, ensuring consistent product quality, efficient processes, and continuous improvement. This certification provides a robust framework for delivering reliable products.

- ASTM Compliance: Our artificial grass products, including those suitable for backyard putting green construction, undergo rigorous testing to meet relevant ASTM (American Society for Testing and Materials) standards for critical performance indicators such as UV stability, flammability, wear resistance, and heavy metal content.

- Lead-Free & Non-Toxic: All our products are rigorously tested to be lead-free and free from other hazardous substances, ensuring they are safe for children, pets, and the environment. We adhere to regulations like California's Proposition 65.

- Partnerships and Service Longevity: With over a decade of dedicated service in the artificial turf industry, we have cultivated strong relationships with leading landscape architects, golf course designers, and installation professionals. Our long-standing presence is a testament to our reliability and expertise.

- Authoritative Citations: Our technical specifications and performance data are often cross-referenced with industry best practices outlined by organizations like the Synthetic Turf Council (STC), ensuring our products meet or exceed general industry benchmarks.

Transparent Deliverables and Support

- Delivery Cycle: We maintain efficient supply chain logistics to ensure timely delivery of your artificial turf. For standard orders, typical delivery takes 2-4 weeks, depending on destination and order size. Expedited shipping options are available upon request. We provide clear communication regarding lead times and tracking information.

- Quality Assurance and Warranty: Our Artificial Grass for Construction Sites product, like all our premium offerings, comes with a robust 10-15 year limited warranty, covering manufacturing defects and significant UV degradation. This warranty reflects our confidence in the product's longevity and performance. Detailed warranty terms are available on our website.

- Comprehensive Customer Support: Our dedicated customer support team is available to assist you at every stage, from initial product selection and technical inquiries to post-installation advice. We offer multiple channels for support:

- Phone Support: Direct access to knowledgeable representatives during business hours.

- Email Support: Responsive and detailed answers to written inquiries.

- Online Resources: Extensive FAQs, installation guides, and product specifications available on our website.

- Design Consultation: Experts available to help tailor our products to your specific backyard putting green construction needs.

Frequently Asked Questions (FAQ) about Artificial Putting Greens

Understanding the intricacies of backyard putting green construction can be complex. Here are answers to some of the most common professional and technical questions we receive:

Q1: What is the optimal pile height for an artificial putting green, and how does it affect play?

A1: The optimal pile height typically ranges from 12mm to 20mm (0.5 to 0.8 inches). Shorter pile heights (e.g., 12-15mm) generally result in a faster Stimp reading, mimicking professional greens, as there is less fiber resistance to the ball. Longer pile heights (e.g., 18-20mm) provide a slightly slower, more forgiving roll, which can be preferred by beginners or for more casual play. The pile height works in conjunction with the infill amount to fine-tune the green's speed.

Q2: What type of infill is best for an artificial putting green, and why is it necessary?

A2: The best infill for artificial putting greens is typically rounded silica sand or specialized acrylic-coated silica sand. Infill is crucial for several reasons: it helps the turf blades stand upright, providing a realistic playing surface; it adds ballast to prevent the turf from shifting; it protects the turf's backing from UV degradation; and it allows for precise control over the ball roll speed (Stimp). Avoid angular sands as they can damage fibers, and crumb rubber is generally not used for putting surfaces due to its bounce characteristics and potential for being carried indoors.

Q3: How important is proper base preparation for the longevity and performance of a backyard putting green?

A3: Proper base preparation is arguably the single most critical factor for the longevity and performance of any artificial putting green. A well-prepared base (typically 3-4 inches of compacted crushed aggregate like decomposed granite) ensures excellent drainage, prevents settling, allows for precise contouring and undulations, and provides a stable foundation for consistent ball roll. Without a solid, well-drained, and compacted base, the green is prone to dips, humps, and drainage issues, significantly compromising its playability and lifespan.

Q4: What is the expected lifespan of a high-quality artificial putting green, such as those made with your Artificial Grass for Construction Sites?

A4: A high-quality artificial putting green, when properly installed and maintained, can last 15-20 years or even longer. Factors influencing lifespan include the quality of the turf fibers (UV stability, material), the durability of the backing (e.g., polyurethane backing on our Artificial Grass for Construction Sites), the quality of the base preparation, and the level of foot traffic and environmental exposure. Our products are designed for maximum durability, ensuring a long-term return on investment.

Q5: Can artificial putting greens be installed on slopes or irregular terrain?

A5: Yes, artificial putting greens offer significant flexibility in design and can be customized to fit various terrains. The base preparation phase allows for the creation of precise slopes, undulations, and breaks, mimicking natural course features. Experienced installers can sculpt the base layer to create challenging contours on virtually any terrain, enhancing the realism and playability of the green. This adaptability is a key advantage of backyard putting green construction.

Q6: What maintenance is required for an artificial putting green?

A6: Artificial putting greens are remarkably low maintenance compared to natural grass, but they are not entirely maintenance-free. Regular maintenance typically involves:

- Brushing: Periodically power brushing the infill to keep the fibers upright and redistribute the infill, maintaining consistent ball roll.

- Debris Removal: Blowing or raking away leaves, twigs, and other organic debris to prevent breakdown and potential weed growth.

- Spot Cleaning: Cleaning up spills or pet waste with water and a mild detergent.

- Weed Control: Though rare, occasional weeds may sprout if seeds land on the infill; these can be easily pulled or treated with a weed killer.

Q7: How does artificial turf impact ball roll and speed (Stimp rating) compared to natural greens?

A7: Modern artificial putting greens can be engineered to replicate the ball roll and speed of natural greens with remarkable accuracy. The Stimp rating (a measure of green speed) is primarily controlled by the turf's pile height, density, and, most critically, the type and amount of infill used. Professional installers can calibrate the infill to achieve a desired Stimp speed, typically ranging from 8 to 12. Unlike natural greens which fluctuate with weather and mowing, artificial greens maintain a consistent speed, offering predictable practice conditions.

Concluding Thoughts: The Future of Personalized Golf Spaces

The rise of high-performance artificial putting greens marks a significant evolution in personal and commercial outdoor recreation. The meticulous process of backyard putting green construction, from the advanced manufacturing of durable materials like our Artificial Grass for Construction Sites to precision installation techniques, ensures a product that excels in aesthetics, durability, and playability. As environmental concerns grow and demands for convenient, low-maintenance solutions increase, artificial turf continues to demonstrate its superiority over natural grass alternatives.

Investing in an artificial putting green is not just about enhancing a property; it's about investing in a lifestyle that prioritizes convenience, sustainability, and year-round access to a beloved sport. The fusion of cutting-edge technology, expert craftsmanship, and a deep understanding of golf mechanics allows for the creation of truly bespoke and high-performing greens. Our commitment to quality, backed by rigorous testing and comprehensive customer support, ensures that your vision for the perfect putting green becomes a tangible and enduring reality.

For further exploration into the technical specifications and industry insights regarding artificial turf applications, we recommend consulting peer-reviewed journals and authoritative industry forums:

- Synthetic Turf Council (STC) Publications: https://www.syntheticturfcouncil.org/page/STC_Publications

- Journal of Sports Engineering and Technology (IJSNET) - search for articles on synthetic surfaces: https://journals.sagepub.com/home/sej

- Golf Course Superintendents Association of America (GCSAA) - for comparative studies on natural vs. synthetic surfaces: https://www.gcsaa.org/

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories