Expert Backyard Putting Green Construction & Installation

Aug . 10, 2025 06:00 Back to list

The Strategic Imperative of Advanced Backyard Putting Green Construction in Modern Commercial and Residential Landscapes

In an era defined by efficiency, sustainability, and bespoke luxury, the demand for sophisticated recreational infrastructure continues its upward trajectory, particularly within the niche yet rapidly expanding sector of personal and commercial golf amenities. The evolution of artificial turf technology has profoundly transformed the feasibility and appeal of creating high-performance golf experiences in diverse environments, culminating in the burgeoning market for backyard putting green construction. This advanced engineering discipline extends far beyond mere aesthetic enhancement, encompassing a meticulous synthesis of geological engineering, material science, and precision landscaping to deliver a consistent, high-fidelity golfing surface that rivals the quality of championship courses. As professional SEO content strategists and technical writers specializing in B2B solutions, we recognize that the decision-making process for such significant investments hinges on a profound understanding of underlying technical specifications, long-term operational benefits, and the intrinsic value proposition offered by leading manufacturers. This comprehensive guide delves into the intricate facets of modern putting green development, exploring the industry's cutting edge trends, the rigorous technical parameters that define superior installations, diverse application scenarios, and the compelling advantages that artificial turf presents over natural grass alternatives. We aim to equip B2B decision-makers, architects, landscape designers, and property developers with the authoritative insights necessary to navigate this specialized field, ensuring informed choices that yield optimal performance, durability, and return on investment. The transition from aspirational concept to tangible, high-performance reality requires a detailed examination of the process, from ground preparation and drainage solutions to the selection of premium synthetic turf and precise infill methodologies, all underscored by adherence to stringent quality control and environmental stewardship. Our discussion will also highlight how products like Hoyarn Grass's Artificial Grass for Construction Sites exemplify the pinnacle of material science and manufacturing precision, offering unparalleled durability and performance across a spectrum of demanding applications, including high-traffic commercial installations and meticulously crafted backyard putting greens, thereby solidifying its position as a preferred choice for discerning clients.

The contemporary landscape of recreational infrastructure is significantly shaped by evolving consumer preferences for low-maintenance, high-performance solutions, a trend that critically underpins the expansion of the artificial putting green market. This shift is not merely driven by convenience but by a sophisticated understanding of resource management, including water conservation and reduced reliance on chemical fertilizers and pesticides, aligning perfectly with global sustainability initiatives. The market for backyard putting green construction is experiencing robust growth, propelled by technological advancements in synthetic fiber manufacturing and installation methodologies that enable a level of realism and playability previously unattainable. According to recent market analyses, the global artificial turf market, which includes components for putting greens, is projected to reach approximately $4.5 billion by 2027, growing at a compound annual growth rate (CAGR) of over 6% from 2020. This growth is a testament to the versatility and inherent advantages of synthetic turf, extending its application from professional sports arenas to intimate residential settings. Furthermore, the aesthetic appeal and long-term cost savings associated with artificial turf, particularly in regions facing water scarcity or stringent environmental regulations, render it an increasingly attractive alternative. Manufacturers are continually innovating, introducing turf products with enhanced UV stability, superior drainage capabilities, and fiber compositions that mimic the subtle nuances of natural grass, thus improving the user experience while simultaneously reducing the ecological footprint. The industry's trajectory is also influenced by rising disposable incomes and a renewed interest in outdoor leisure activities, especially in post-pandemic scenarios, fostering an environment ripe for specialized recreational installations. This confluence of technological innovation, environmental consciousness, and shifting consumer demand positions artificial putting green construction as a pivotal segment within the broader landscape and recreational development industry, offering significant opportunities for B2B enterprises capable of delivering high-quality, customized solutions.

The Engineering Blueprint: A Comprehensive Overview of Artificial Putting Green Construction Methodologies

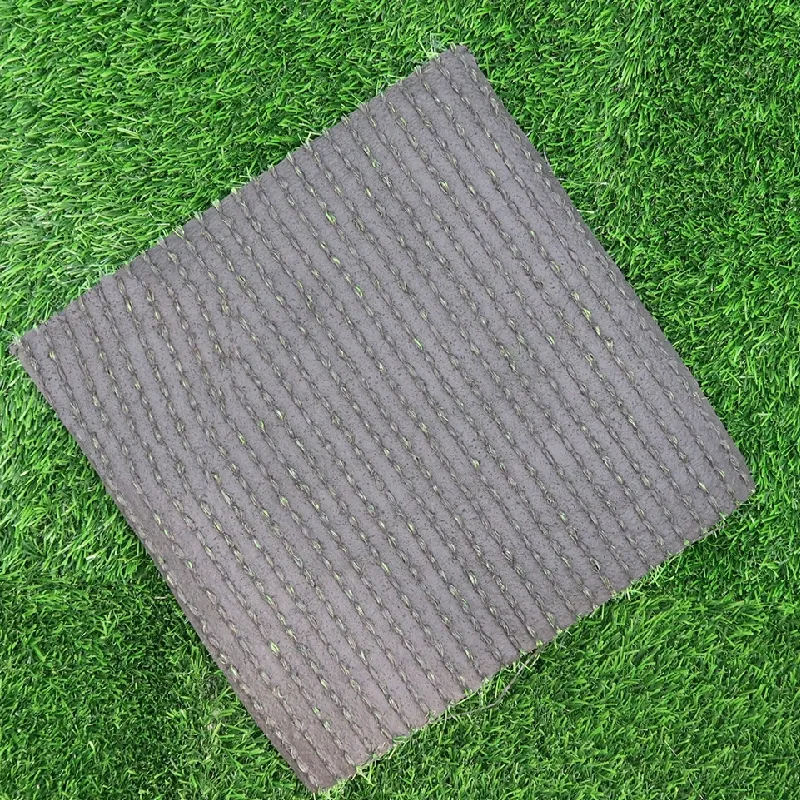

The successful execution of an backyard putting green construction project necessitates a rigorous adherence to a multi-stage engineering blueprint, transforming a conceptual design into a high-performance golfing surface. This process is far more complex than a simple laying of turf; it is an intricate interplay of civil engineering principles, material science, and precision landscaping. The initial phase, crucial for long-term stability and drainage, involves meticulous site preparation, beginning with excavation to the desired depth and contouring of the sub-base. This establishes the undulations and breaks that define the putting challenge. Following excavation, a robust base layer is installed, typically composed of compacted aggregate, such as crushed granite or limestone, which provides structural integrity and ensures consistent surface performance. The thickness of this base can range from 4 to 8 inches, depending on soil conditions, climate, and anticipated traffic, with a minimum compaction rate of 95% Modified Proctor Density to prevent settling. Proper drainage is paramount; a permeable geotextile fabric may be laid beneath the aggregate to prevent soil migration and enhance water flow, complemented by a perimeter drainage system or strategic grading to channel water away from the green. On top of the compacted aggregate, a finer, permeable layer, often of decomposed granite or specific rock dust, is meticulously applied and laser-graded to achieve the precise contours and stimp speed requirements. This layer is then wetted and compacted to create an incredibly stable and smooth foundation. The manufacturing process of the artificial turf itself, while occurring off-site, dictates critical performance parameters. Premium artificial grass, such as the `Artificial Grass for Construction Sites` from Hoyarn Grass, utilizes high-density polyethylene (PE) or polypropylene (PP) fibers for durability and realistic play, often featuring a blend of fiber shapes (e.g., C-shaped, S-shaped) to enhance resilience and rebound. The tufting process stitches these fibers into a robust, often polyurethane-coated, backing that provides dimensional stability and excellent tuft bind, preventing fiber pull-out. This backing is typically perforated to ensure superior drainage. Quality control is maintained through adherence to international standards like ISO 9001 for manufacturing quality management and ISO 14001 for environmental management, alongside ASTM F1551 for specific turf properties such as pile height, face weight, and permeability, and ISO 17025 for testing laboratory competence. The installation of the turf involves carefully unrolling the large turf rolls, ensuring proper alignment of the grain, precise cutting to fit the contours and cup holes, and seaming the sections together using specialized adhesive tapes and robust outdoor adhesives designed to withstand environmental extremes. Post-installation, the infill material, typically silica sand or an acrylic-coated sand, is uniformly broadcast into the turf fibers. This infill provides ballast, supports the fibers, enhances ball roll characteristics (stimp speed), and protects the backing from UV degradation. The type and quantity of infill are meticulously calibrated to achieve specific stimp ratings, which measure the speed of a golf ball on the surface. The entire system is designed for an impressive operational lifespan, often exceeding 15-20 years with proper maintenance, making it a highly sustainable solution. In industries such as recreational landscaping, commercial property development, and even specialized training facilities, the advantages of a precisely engineered artificial putting green are profound: significant water savings (up to 70% compared to natural grass), elimination of harmful pesticides and fertilizers, consistent playability regardless of weather, and drastically reduced maintenance costs, all while resisting corrosion and degradation from environmental elements.

Deconstructing Performance: Key Technical Parameters and Specifications for Optimal Backyard Putting Greens

The performance and longevity of any backyard putting green construction project are directly correlated with the precise adherence to and understanding of critical technical parameters and material specifications. These parameters collectively define the playability, durability, and aesthetic appeal of the final installation, ensuring that the investment yields a high-fidelity golfing experience for decades. A primary specification is the "pile height" or "blade length" of the artificial turf, which for putting greens typically ranges from 0.5 inches to 1.5 inches. Shorter pile heights generally provide faster ball roll, mimicking closely mown natural greens. Coupled with pile height is "face weight," measured in ounces per square yard, representing the total weight of the fibers. Higher face weights usually indicate a denser, more robust turf, often translating to greater durability and a more luxurious feel. For putting greens, face weights can range from 40 to 90 oz/sq yd. "Stitch rate" and "gauge" further describe turf density; stitch rate refers to the number of stitches per linear foot, while gauge indicates the distance between stitch rows. A tighter stitch rate and narrower gauge contribute to a denser turf, essential for consistent ball roll and resistance to matting. The material composition of the turf fibers is another crucial technical parameter. Most premium artificial putting greens utilize advanced polyethylene (PE) or nylon fibers due to their superior resilience, UV stability, and natural appearance. Nylon is particularly effective for putting greens due to its excellent memory and stiffness, allowing it to stand up to heavy traffic and maintain its upright position, directly influencing ball roll. The backing system, typically a multi-layered woven polypropylene fabric with a polyurethane or latex coating, is vital for dimensional stability, preventing shrinkage or expansion due to temperature fluctuations, and ensuring high "tuft bind" strength, which prevents fibers from detaching. Permeability, measured in inches per hour (e.g., 30+ inches/hour), is a critical technical specification for the entire putting green system, from the turf backing to the base layers. This ensures rapid water drainage, preventing pooling and maintaining playability even after heavy rainfall, thereby enhancing the functional lifespan and reducing maintenance burdens. The "infill" material – often high-grade silica sand or an acrylic-coated variant – is meticulously applied and brushed into the turf fibers. Its particle size distribution, hardness, and weight are technically specified to provide optimal ballast, protect the fibers from excessive wear, enhance fiber uprightness, and crucially, regulate the "stimp rating." The stimp rating, a measure of ball roll speed, can be precisely calibrated through infill type and quantity, allowing for customized play characteristics, typically ranging from 8 to 12 on the stimpmeter scale for residential and commercial putting greens. Furthermore, the base construction, comprising compacted aggregate layers, must meet specific engineering standards for density (e.g., 95% compaction per ASTM D1557) and depth to ensure stability and prevent settling over time, which could lead to an uneven playing surface. Comprehensive testing protocols, including ASTM F1551 for synthetic turf and ISO standards for material quality, ensure that products meet specified performance benchmarks for tear strength, UV degradation, and wear resistance, guaranteeing the integrity and longevity of the artificial putting green construction.

| Parameter | Description | Typical Range for Putting Greens | Impact on Performance |

|---|---|---|---|

| Pile Height | Length of the individual turf fibers from the backing. | 0.5 - 1.5 inches (12-38 mm) | Shorter pile for faster roll; critical for stimp rating. |

| Face Weight | Weight of the turf fibers per square yard (excluding backing and infill). | 40 - 90 oz/sq yd (1350-3050 g/sq m) | Higher weight indicates denser, more durable turf; influences feel and longevity. |

| Material Composition | Primary polymer used for the turf fibers. | Polyethylene (PE) or Nylon (PA) | PE offers softness and natural look, Nylon offers superior resilience and memory for putting. |

| Backing Material | The material that holds the turf fibers in place. | Polyurethane (PU) or Latex coated polypropylene | Ensures tuft bind, dimensional stability, and drainage. PU is generally superior. |

| Stitch Rate | Number of stitches per linear unit (e.g., per 10 cm). | 18-24 stitches/10 cm (variable based on product) | Higher stitch rate implies denser turf, better for consistent ball roll. |

| Gauge | Distance between stitch rows. | 3/8", 5/8", 3/4" (9.5mm, 15.8mm, 19mm) | Influences overall turf density and appearance. |

| Permeability/Drainage Rate | Rate at which water drains through the turf system. | 30+ inches per hour (via backing perforations) | Ensures rapid water shedding, preventing pooling and maintaining playability. |

| Infill Type & Quantity | Material (e.g., silica sand, coated sand) and amount distributed within fibers. | 2-5 lbs/sq ft (for putting), specialized particle size | Provides ballast, fiber support, UV protection, and precisely controls stimp rating. |

| Stimp Rating Range | Measurement of ball roll speed on the green surface. | 8 - 12 (customizable) | Determines the 'fastness' of the green, mimicking natural course conditions. |

| UV Stability (ISO 4892) | Resistance to degradation from ultraviolet radiation. | ≥ 6,000 hours QUV-B or Xenon Arc testing | Prevents fading, embrittlement, and ensures color retention over time. |

| Lifespan Expectancy | Anticipated functional life of the installed system. | 15 - 20 years with proper maintenance | Indicates long-term value and ROI. |

Versatility in Application: Broadening the Horizons of Artificial Turf Beyond Residential Putting Greens

While the phrase backyard putting green construction primarily evokes images of residential luxury, the underlying technology and robust nature of advanced artificial turf, exemplified by products like Hoyarn Grass's `Artificial Grass for Construction Sites`, unlock a far broader spectrum of application scenarios, particularly within the B2B landscape. Beyond bespoke residential installations that cater to private golf enthusiasts, the commercial potential of these high-performance synthetic surfaces is immense. Consider corporate campuses and office buildings, where an artificial putting green can serve as a unique amenity, fostering employee well-being, team-building activities, and providing a distinctive space for client entertainment. Such installations require turf systems capable of withstanding higher traffic volumes and diverse environmental stresses, necessitating materials with superior wear resistance and consistent performance characteristics, directly aligning with the robust design principles of turf engineered for demanding construction sites. Similarly, within the hospitality sector, luxury hotels, resorts, and cruise ships are increasingly integrating artificial putting greens and golf simulators to enhance guest experiences, offering year-round recreational opportunities that are impervious to weather conditions and require minimal operational overhead compared to natural greens. These applications often demand not only performance but also exceptional aesthetic appeal, seamlessly blending into sophisticated architectural designs. Educational institutions, from universities to specialized sports academies, also benefit significantly from the versatility of `artificial turf construction`. These greens can provide dedicated practice areas for golf teams, physical education classes, or even contribute to campus beautification, offering durable, low-maintenance green spaces. The non-permeability and resilience of synthetic turf, a hallmark of its design for demanding construction sites, translates perfectly to these high-traffic, multi-use environments, ensuring longevity and consistent play. Furthermore, urban developments and public parks are exploring artificial putting greens as innovative recreational zones that address the challenges of water scarcity and maintenance costs inherent in traditional landscaping. These spaces require turf solutions that are exceptionally durable, vandal-resistant, and capable of handling intense public use, reinforcing the value proposition of turf designed for robust construction applications. Beyond golf, the core technology of artificial turf is being applied to various sports and recreational surfaces, including bocce ball courts, croquet lawns, and even specialized agility training areas, all benefiting from the consistent, low-maintenance surface provided by advanced synthetic materials. The product's inherent resistance to harsh chemicals, extreme temperatures, and heavy foot traffic makes it ideal for these diverse applications, where natural grass would rapidly degrade or prove prohibitively expensive to maintain. This broad applicability underscores the strategic value of partnering with a manufacturer like Hoyarn Grass, whose expertise in durable artificial grass for construction sites directly translates into superior, long-lasting solutions for any ambitious putting green or recreational surface project, ensuring performance consistency, environmental responsibility, and significant long-term operational savings across an extensive array of commercial and institutional settings.

Strategic Advantages: Why Artificial Grass Elevates Backyard Putting Green Construction to a Superior Investment

The decision to invest in backyard putting green construction using advanced artificial turf represents a strategic advantage for commercial and residential developers, offering a compelling array of benefits that far outweigh the initial outlay compared to traditional natural grass installations. Foremost among these is the unparalleled consistency in playability. Unlike natural greens, which are subject to variations due to weather, growth patterns, and maintenance cycles, an artificial putting green delivers a uniform surface with a predictable ball roll (stimp rating) day after day, year after year. This consistency is crucial for golf enthusiasts seeking to refine their short game without the interruptions caused by adverse weather conditions or seasonal changes. This uniform performance is directly attributable to the precise engineering of synthetic fibers, the stable base construction, and the controlled application of infill, elements that contribute to the robust design inherent in products like Hoyarn Grass's `Artificial Grass for Construction Sites`. Secondly, the environmental benefits are substantial and align with contemporary sustainability mandates. Artificial putting greens eliminate the need for significant water consumption, a critical consideration in regions facing drought or water restrictions. An average natural putting green requires thousands of gallons of water annually for irrigation, whereas an artificial one requires minimal water for occasional rinsing, leading to massive savings in utility costs and a reduced ecological footprint. Furthermore, the reliance on chemical fertilizers, pesticides, and herbicides is completely negated, preventing harmful runoff into local ecosystems and safeguarding human health. This not only contributes to environmental preservation but also reduces the operational expenses associated with chemical procurement and application. Thirdly, the long-term cost savings associated with drastically reduced maintenance are a primary driver for B2B adoption. Natural greens demand constant attention: daily mowing, aerating, fertilizing, pest control, and disease management, all requiring specialized equipment and skilled labor. In contrast, an artificial putting green requires only occasional brushing, blowing, and infill replenishment over its typical 15-20 year lifespan. This translates to substantial savings in labor, equipment, fuel, and chemical costs, delivering a tangible return on investment over the product's lifecycle. Manufacturers often cite maintenance cost reductions of up to 70-80% compared to natural grass. Fourthly, the inherent durability and resilience of modern artificial turf, designed for high-traffic environments and `artificial turf construction` applications, ensure a robust and long-lasting installation. Premium synthetic fibers are UV-stabilized to prevent fading and degradation from sun exposure, engineered for superior wear resistance, and designed to withstand extreme temperatures, from freezing winters to scorching summers, without compromising structural integrity or aesthetic appeal. This makes them ideal for both residential and demanding commercial settings. Finally, the aesthetic versatility and customizability offered by artificial turf are significant. Architects and landscape designers can create virtually any contour, break, or hole placement, providing limitless design freedom to craft unique and challenging putting experiences that integrate seamlessly with the surrounding landscape, enhancing property value and visual appeal. These combined advantages underscore why `artificial putting green construction` is not merely a luxury but a pragmatic, high-performance, and sustainable investment for modern properties.

Strategic Manufacturer Selection: Benchmarking Excellence in Artificial Turf for Backyard Putting Green Construction

Selecting the right manufacturer is a pivotal decision in any significant B2B procurement, and for backyard putting green construction, this choice directly impacts the quality, longevity, and return on investment of the final product. While specific brand comparisons might vary based on regional availability and project specifics, the criteria for evaluating manufacturers remain universal and are critical for informed decision-making. First and foremost is the manufacturer's demonstrated expertise in artificial turf technology, particularly for putting green applications. This involves evaluating their R&D capabilities, patents, and track record of innovation in fiber composition, backing materials, and infill systems. A reputable manufacturer will often specialize in distinct turf categories, demonstrating deep understanding of the unique performance requirements for golf surfaces, contrasting with generalist turf suppliers. For instance, a company renowned for `Artificial Grass for Construction Sites` demonstrates a commitment to durability, wear resistance, and high-performance under demanding conditions, attributes directly transferable and highly beneficial for a premium putting green. Secondly, product quality and adherence to international standards are non-negotiable. Manufacturers should provide transparent data on material specifications, including fiber denier, face weight, pile height, UV stability (e.g., ISO 4892 testing to withstand thousands of hours of accelerated weathering), and permeability. Certifications such as ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) attest to rigorous manufacturing processes and environmental responsibility. Furthermore, independent third-party testing reports, such as those from SGS, ASTM, or FIFA (though specific to sports fields, their testing methodologies for wear and durability are relevant), provide objective validation of performance claims, including critical aspects like tuft bind, tear strength, and heavy metal content. Thirdly, customization capabilities and technical support are vital for B2B clients. The ability to tailor turf specifications—such as pile height, fiber type (e.g., nylon for ultra-fast greens), and infill recommendations—to achieve specific stimp ratings or design aesthetics is a hallmark of a client-centric manufacturer. This extends to pre-sales consultation, detailed project planning assistance, and post-installation technical support, including guidance on maintenance and troubleshooting. Hoyarn Grass, with its expertise in bespoke turf solutions, exemplifies this dedication to comprehensive client engagement. Fourthly, a manufacturer's service history and industry reputation are strong indicators of trustworthiness and reliability. This includes their years in operation, the scale and diversity of their completed projects (e.g., commercial complexes, golf courses, sports arenas, high-end residential installations), and public testimonials or case studies that demonstrate their commitment to customer satisfaction and problem resolution. A transparent warranty policy, typically ranging from 8 to 15 years for UV degradation and product defects, further underscores a manufacturer’s confidence in their product’s longevity. Finally, supply chain robustness and logistical capabilities are crucial for timely project completion. Manufacturers with established global distribution networks and efficient logistics can ensure on-time delivery of materials, minimizing project delays and cost overruns. By meticulously evaluating these criteria, B2B decision-makers can confidently select a manufacturing partner that provides not just turf, but a complete, high-quality solution engineered for the demands of `artificial putting green construction`.

Tailored Excellence: Custom Solutions and Bespoke Design in Artificial Putting Green Construction

The demand for bespoke recreational spaces has driven a significant evolution in the field of backyard putting green construction, transforming it from a standardized product into a highly customizable solution meticulously tailored to client specifications and site unique characteristics. This capacity for customization is a crucial differentiator for manufacturers and installers serving the discerning B2B market. Customization begins with the design phase, where architects, landscape designers, and clients collaborate to define the desired dimensions, contours, breaks, and hole placements of the putting green. Advanced 3D modeling and CAD software are often employed to visualize the precise topography, allowing for iterative adjustments to achieve the perfect balance of challenge and playability. This level of detail in design ensures that each putting green is a unique masterpiece, reflecting the client's vision and integrating seamlessly with the existing landscape or architectural blueprint. Furthermore, the selection of turf material itself offers extensive customization options. Beyond the standard putting green turf, hybrid systems might incorporate fringe and rough sections using different pile heights, face weights, and fiber types (e.g., longer, softer fibers for the rough, denser, firmer fibers for the fringe) to simulate a full golf experience. This modular approach allows for the creation of multi-functional practice areas that can accommodate chipping, pitching, and putting, catering to varying skill levels and training objectives. The technical specifications of the infill material can also be precisely calibrated to achieve a desired stimp rating, allowing for greens to be designed for slower, more leisurely play or for faster, championship-level speeds. For example, a commercial golf training facility might require a stimp rating of 10-12 to replicate professional course conditions, while a residential client might prefer a more forgiving 8-9. This precision in performance tuning is a testament to the advanced material science underpinning modern `artificial turf construction`. Beyond the core green, manufacturers and installers can integrate a variety of ancillary features, including sophisticated drainage systems designed for specific soil conditions and rainfall patterns, LED lighting for evening play, integrated sound systems, and even subsurface heating elements for year-round usability in colder climates. The ability to incorporate natural elements like rock features, waterfalls, or native plants around the artificial green further enhances its aesthetic appeal and ecological integration. For large-scale commercial projects, such as corporate entertainment facilities or resort amenities, the custom solution extends to project management, including phased construction, minimal disruption to ongoing operations, and comprehensive post-installation support. A manufacturer like Hoyarn Grass, with a strong background in providing `Artificial Grass for Construction Sites`, brings a robust project management discipline and the capacity to scale solutions to meet the most demanding project requirements, ensuring a smooth, efficient, and successful implementation of complex custom designs. This holistic approach to bespoke design and implementation underscores the value proposition of modern `artificial putting green construction` as a highly adaptable and client-centric investment.

Real-World Impact and Assured Confidence: Case Studies, Quality Control, and Client Support in Artificial Putting Green Construction

The efficacy and reliability of backyard putting green construction are best demonstrated through tangible real-world applications and comprehensive client support frameworks, showcasing the profound impact of advanced artificial turf solutions on diverse B2B and residential projects. Consider a recent high-profile case study involving a luxury residential development in a drought-prone region. The developer opted for over 5,000 square feet of interconnected artificial putting greens and chipping areas throughout the community. This choice was driven primarily by the need for significant water conservation, reducing landscape water consumption by an estimated 80% compared to conventional natural grass installations. The project utilized a high-density, low-pile artificial turf specifically engineered for putting greens, combined with a permeable aggregate base. Rigorous pre-installation testing of the turf’s drainage rate (exceeding 40 inches per hour) ensured superior water management, eliminating standing water and maintaining playability even after torrential rains. Post-installation, resident feedback highlighted the consistent stimp speed (calibrated to a consistent 10 on the stimpmeter), the natural aesthetic, and the virtually maintenance-free nature of the greens, contributing significantly to property value and resident satisfaction. In another instance, a leading corporate campus sought to enhance employee wellness and offer unique recreational amenities. They commissioned an `artificial turf construction` of a 2,500 sq ft putting and short-game practice area adjacent to their main office building. The primary challenge was integrating a high-performance golf surface into a high-traffic urban environment while minimizing disruption during installation. The solution involved utilizing Hoyarn Grass's `Artificial Grass for Construction Sites`, chosen for its exceptional durability, ease of installation, and resilience to heavy foot traffic. The project was completed within a tight 4-week schedule, with minimal impact on daily operations. Employees reported a marked increase in engagement with the outdoor space, using the putting green for lunch breaks, informal meetings, and after-work unwinding, demonstrating how strategic amenities can foster a more positive and productive work environment. The long-term performance of these installations is underpinned by robust quality control protocols implemented by reputable manufacturers. This includes multi-stage inspections during turf manufacturing, from raw material verification (e.g., polymer purity, UV stabilizer content) to final product testing (e.g., tuft bind strength, tear resistance, critical fall height for surrounding areas if applicable). Adherence to ISO 9001 quality management ensures consistency across batches, while environmental certifications like ISO 14001 confirm responsible manufacturing practices. Post-installation, comprehensive warranties provide peace of mind. A typical warranty for a premium artificial putting green ranges from 8 to 15 years, covering defects in materials and significant UV degradation, safeguarding the client’s investment. Furthermore, leading suppliers offer extensive customer support, including detailed installation guides, maintenance recommendations, and dedicated technical assistance for any issues that may arise. Delivery schedules are meticulously planned, with logistics teams coordinating with project managers to ensure on-time material delivery, minimizing site delays. This holistic approach, from initial consultation and bespoke design to rigorous quality assurance and unwavering post-sales support, ensures that every `artificial putting green construction` project delivers on its promise of unparalleled performance, longevity, and client satisfaction, solidifying the manufacturer’s role as a trusted partner.

Common Inquiries and Long-Term Assurance: FAQs, Delivery, and Warranty Commitments for Artificial Putting Greens

For B2B stakeholders considering an investment in backyard putting green construction, a clear understanding of frequently asked questions (FAQs) alongside robust commitments to delivery, warranty, and ongoing support is paramount to building confidence and ensuring a successful project. Addressing these concerns proactively demonstrates a manufacturer's expertise and trustworthiness.

Frequently Asked Questions (FAQs)

-

Q1: How long does an artificial putting green last?

A1: A professionally installed artificial putting green, utilizing high-quality turf materials and proper base construction, typically has an operational lifespan of 15 to 20 years. Premium products, such as those designed for demanding `artificial turf construction` like Hoyarn Grass's Artificial Grass for Construction Sites, are engineered with advanced UV stabilizers and durable fibers (e.g., nylon or robust polyethylene) that resist degradation from sunlight, extreme temperatures, and heavy use. The longevity is also significantly influenced by the quality of the base preparation and infill material, which protect the turf fibers and backing from wear and tear, ensuring consistent performance for decades with minimal maintenance.

-

Q2: Is artificial turf for putting greens truly low-maintenance?

A2: Yes, a key advantage of `artificial putting green construction` is its significantly reduced maintenance requirements compared to natural grass. While natural greens demand daily mowing, fertilizing, watering, aerating, and pest control, artificial greens primarily require occasional brushing to maintain fiber uprightness, blowing off debris, and potentially a light top-up of infill every few years. This translates to substantial savings in labor, equipment costs, water usage, and chemical expenses, making it an economically efficient long-term solution for both residential and commercial properties.

-

Q3: How does the ball roll compare to a natural green?

A3: Modern `artificial turf construction` technology allows for an extremely realistic and consistent ball roll, often mimicking the stimp speeds of championship natural greens. The precise control over pile height, fiber density, and particularly the type and quantity of infill material enables the putting green to be calibrated to a specific stimp rating, typically ranging from 8 to 12. This consistency is a major advantage, as it provides a predictable practice surface regardless of weather conditions, which is invaluable for serious golfers and golf training facilities.

-

Q4: What about drainage? Will water pool on the green?

A4: Proper drainage is a fundamental aspect of high-quality backyard putting green construction. Reputable manufacturers design turf with permeable backings (perforated to allow water to pass through), and the underlying base structure includes multiple layers of compacted, permeable aggregate. This system is engineered to manage significant rainfall efficiently, preventing water pooling on the surface. Drainage rates can often exceed 30 inches per hour, ensuring rapid water shedding and immediate playability after rain.

-

Q5: Can the putting green be customized to my specific design preferences?

A5: Absolutely. Modern `artificial putting green construction` offers extensive customization. This includes defining the exact shape, size, contours, undulations, and break of the green. Clients can specify the number and placement of cup holes, integrate chipping areas, and even incorporate fringe and rough zones using different turf types. Advanced design software allows for detailed visualization and iterative adjustments to create a truly unique and personalized golfing experience tailored to specific skill levels or aesthetic requirements.

Delivery Schedules and Logistics

For B2B projects, timely and efficient delivery is crucial to maintaining project timelines and budget. Leading manufacturers like Hoyarn Grass prioritize robust supply chain management to ensure prompt dispatch of materials. Standard delivery times for artificial turf rolls and associated infill materials typically range from 2 to 4 weeks, depending on the order size, customization requirements, and destination. For large-scale or international projects, detailed logistics plans are developed, including options for expedited shipping and direct coordination with on-site project managers. Clients receive transparent communication regarding lead times, shipping estimates, and tracking information, enabling seamless integration of turf delivery into broader construction schedules. Our commitment to reliable logistics minimizes potential delays and ensures that high-quality materials, including our Artificial Grass for Construction Sites, arrive precisely when needed for your `artificial turf construction` endeavor.

Warranty and Customer Support

Confidence in an investment is solidified by comprehensive warranty coverage and unwavering customer support. Reputable artificial turf manufacturers typically offer an industry-standard warranty ranging from 8 to 15 years against manufacturing defects, excessive UV degradation (fading), and material deterioration under normal use. This warranty covers the integrity of the turf fibers and backing, providing assurance for the long-term performance of your backyard putting green construction. Beyond the initial warranty, dedicated customer support teams are available to address any post-installation inquiries, provide maintenance guidance, and assist with any unforeseen issues. This commitment extends to providing detailed product documentation, maintenance guides, and access to technical experts who can offer tailored advice for optimizing the longevity and performance of your artificial putting green. This holistic approach to client care underscores our dedication to not just selling a product, but providing a complete, long-term solution backed by reliability and expert assistance.

Further Reading and Resources:

- ASTM D1557-12: Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (12,400 ft-lbf/ft³ (600 kN-m/m³)) - Provides insights into base layer compaction standards.

- ISO 9001: Quality Management Systems – Requirements - Global standard for quality management in manufacturing.

- SGS: Synthetic Turf Testing Services - Independent third-party testing for artificial turf performance and safety.

- Golf Course Superintendents Association of America (GCSAA): Putting Green Construction - Valuable insights on green design and maintenance for natural and synthetic surfaces.

- Synthetic Turf Council: FAQs - Industry organization providing information on artificial turf applications and benefits.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories