Playground Artificial Turf Price: Durable & Safe Grass for Kids

Sep . 15, 2025 10:20 Back to list

Strategic Investment: Navigating the playground artificial turf price Landscape

In the rapidly evolving landscape of urban development and educational infrastructure, the selection of appropriate surfacing for play areas is a critical decision. Beyond immediate aesthetics, factors such as safety, durability, maintenance costs, and long-term environmental impact significantly influence procurement choices. This article delves into the multifaceted aspects surrounding playground artificial turf price, offering a comprehensive analysis for B2B stakeholders considering this essential investment. We aim to equip decision-makers with the technical insights needed to evaluate options, understand manufacturing intricacies, and project the total cost of ownership (TCO) for superior, long-lasting playground solutions.

Industry Trends in High-Performance Playground Surfacing

The demand for safe, sustainable, and aesthetically pleasing play surfaces continues to accelerate globally. Key trends influencing the market for artificial grass for playgrounds include:

- Enhanced Safety Standards: A heightened focus on critical fall height (CFH) ratings, shock absorption, and impact attenuation to prevent injuries, driving innovation in infill systems and turf backing.

- Sustainability & Eco-Consciousness: Increased preference for products made from recycled materials, water-efficient solutions, and those free from harmful chemicals (e.g., lead, heavy metals, PFOA/PFOS).

- Durability & Longevity: Investment in turf systems designed to withstand heavy foot traffic, extreme weather conditions, and UV exposure for extended lifespans, minimizing replacement cycles.

- Customization & Design Flexibility: The ability to integrate diverse colors, patterns, and logos to create engaging and branded play environments.

- Low Maintenance Regimes: A shift towards surfaces that require minimal upkeep, reducing operational costs for schools, municipalities, and commercial entities.

These trends directly impact the design, material selection, and ultimately, the playground artificial turf price, reflecting a market demand for value-driven, high-performance solutions.

Understanding the Manufacturing Process: Shaping the playground artificial turf price

The sophisticated manufacturing process behind high-quality playground artificial turf is a primary determinant of its performance, durability, and cost. Below is a detailed overview:

1. Raw Material Sourcing & Extrusion

Materials: High-grade Polyethylene (PE) for softness and Polypropylene (PP) for strength, UV stabilizers, color pigments, and anti-aging additives. Recycled content is increasingly integrated. The blend dictates yarn performance.

Process: Polymer pellets are melted and extruded through spinnerets to form continuous filaments (yarns). These are then twisted, texturized, and heat-set to create specific fiber profiles (e.g., monofilament, fibrillated, slit-film) that impact resilience and aesthetics. This precision process is crucial for yarn integrity.

2. Tufting & Backing Application

Process: The manufactured yarn is fed into a tufting machine, which uses multiple needles to stitch the fibers into a primary backing material (typically woven polypropylene). The density of stitches (gauge and stitch rate) is meticulously controlled to meet desired pile height and density specifications for specific critical fall height ratings.

Backing: A secondary backing, often made of latex or polyurethane, is then applied to firmly bind the tufted fibers, enhancing dimensional stability, strength, and extending the service life. Polyurethane backings offer superior durability and resistance to moisture.

3. Perforation & Quality Control

Process: The finished turf roll undergoes perforation to create drainage holes, ensuring efficient water runoff and preventing puddling, which is vital for all-weather playability and hygiene. Hole size and density are engineered for optimal drainage capacity.

Testing Standards: Rigorous quality control is applied at every stage. This includes adhesion tests for tuft bind, tensile strength tests for backing materials, UV resistance testing (ASTM G155), flammability tests (ASTM E648), and heavy metal content analysis. Products often meet international standards like ISO 9001 (Quality Management) and critical playground safety standards such as ASTM F1292 (Impact Attenuation) and ASTM F1951 (Accessibility).

4. Finishing & Packaging

Process: The turf is trimmed to exact dimensions, inspected for any defects, and rolled onto cores for shipment. Specialized packaging protects the turf during transit. Each batch is meticulously documented.

Service Life: High-quality turf, subject to proper installation and maintenance, offers a service life of 10-15 years, often supported by extensive warranties. This significantly impacts the long-term playground artificial turf price as an investment.

Illustration of the multi-stage manufacturing process for high-quality artificial playground turf.

Target Industries & Application Advantages: This rigorous manufacturing process yields turf ideal for municipal parks, educational institutions (schools, kindergartens), commercial recreation centers, and residential play areas. Advantages in typical application scenarios include enhanced energy saving through reduced water consumption and maintenance, superior corrosion resistance (to elements), and consistent safety performance irrespective of weather conditions, delivering a strong ROI.

Technical Specifications: Artificial Turf For Green Playgrounds, Boundless Energy

Product specifications are paramount for ensuring performance and compliance. Our "Artificial Turf For Green Playgrounds, Boundless Energy" product exemplifies high-grade engineering designed for demanding play environments. Understanding these details is key to assessing the value proposition of the playground artificial turf price.

| Parameter | Specification | Technical Rationale |

|---|---|---|

| Product Name | Artificial Turf For Green Playgrounds, Boundless Energy | Engineered for vibrant aesthetics and high-impact play. |

| Yarn Type | PE Monofilament with Thatch Layer (PP) | Monofilament provides softness and realistic appearance; PP thatch adds density, support, and reduces infill splash. |

| Pile Height | 40mm (approx. 1.57 inches) | Optimal balance for fall protection, natural feel, and infill retention for playgrounds. |

| Gauge | 3/8 inch | Indicates yarn density; 3/8" is standard for durable, dense turf. |

| Stitch Rate | 180-200 stitches/meter | Higher stitch rate translates to a denser, more resilient surface, contributing to longevity. |

| Dtex | 12,000 (total, including thatch) | Denier per tex; higher Dtex signifies thicker, more durable yarn fibers. |

| Backing Material | Double PP Cloth + SBR Latex (or PU optional) | Double layer enhances stability; SBR Latex offers strong tuft bind, PU offers superior dimensional stability and drainage. |

| Infill Recommendation | Silica Sand (15-20 kg/sqm) + Crumb Rubber (SBR/TPE/EPDM, 5-10 kg/sqm) | Critical for ballast, yarn support, and impact attenuation; tailored for CFH requirements. |

| Critical Fall Height (CFH) | Up to 2.5 meters (8.2 feet) with appropriate infill and shock pad system. | Meets ASTM F1292 standards, crucial for playground safety compliance. |

| UV Stability | DIN 53387 > 6000 hours (Grade 4-5) | Ensures color retention and material integrity against prolonged sun exposure. |

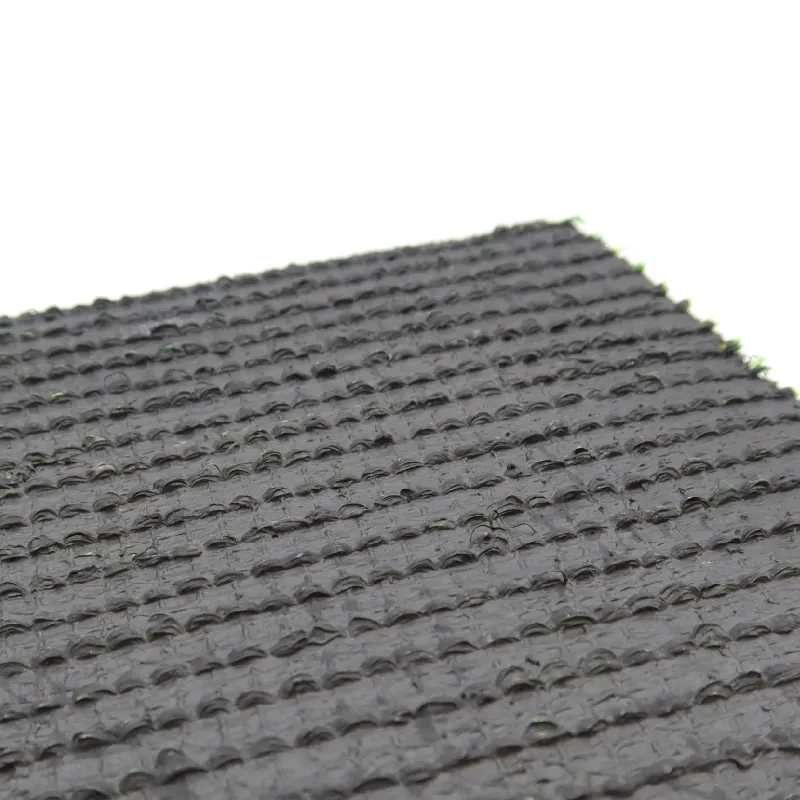

Detailed view of high-performance artificial turf fibers and backing.

Key Technical Advantages of Modern Artificial Grass for Playgrounds

Investing in advanced artificial grass for playgrounds offers a multitude of technical and operational advantages over natural grass or traditional safety surfacing materials:

- Unmatched Safety Performance: Engineered systems with integrated shock pads and specific infill materials achieve precise Critical Fall Height (CFH) ratings, often exceeding the safety capabilities of loose-fill materials or natural grass, which can become compacted or uneven. This adherence to ASTM F1292 provides peace of mind.

- Superior Durability & Longevity: High-denier yarns with robust UV stabilization ensure the turf maintains its aesthetic appeal and structural integrity for over a decade, resisting fading, degradation, and heavy foot traffic. The strong tuft bind and advanced backing prevent fiber detachment.

- Consistent Playability, All Weather: Excellent drainage systems (perforated backing) prevent standing water, allowing playgrounds to remain operational even after heavy rainfall. This reduces downtime and maximizes usage compared to natural grass which can become muddy or waterlogged.

- Reduced Maintenance & Operational Costs: Eliminates the need for mowing, watering, fertilizing, and pest control. This significantly lowers labor costs, utility bills (water), and chemical expenditures, contributing to a lower total cost of ownership over its lifespan, which directly impacts the playground artificial turf price equation.

- Enhanced Hygiene & Allergy Reduction: Artificial turf does not harbor pollen or provide an environment for insects, reducing allergen exposure and contributing to a cleaner play space. Its non-organic nature prevents mud and dirt tracking into facilities.

- Environmental Benefits: Significant water conservation, elimination of harmful pesticides and fertilizers, and often manufactured with recycled content, contributing to LEED certification eligibility for sustainable building projects.

Children enjoying a vibrant and safe artificial turf playground.

Application Scenarios & Customized Solutions for Artificial Grass for Playgrounds

The versatility of modern artificial turf extends its application across a broad spectrum of play environments, each benefiting from tailored solutions:

- Educational Institutions: From kindergarten outdoor areas to primary and secondary school playgrounds, turf provides a durable, safe, and clean surface that withstands intensive daily use. Custom designs can incorporate learning elements or school logos.

- Municipal Parks & Public Playgrounds: Ideal for high-traffic public spaces where consistent appearance and minimal maintenance are crucial. The ability to integrate specific CFH requirements for different play structures is invaluable.

- Commercial & Residential Developments: Enhances the aesthetic and functional value of apartment complexes, community centers, and large residential estates by providing attractive, low-maintenance play zones.

- Indoor Play Areas: Offers a clean, hypoallergenic, and impact-absorbing surface for indoor recreation zones, often specified with non-infill or low-infill systems.

Customization Capabilities:

Beyond standard green, suppliers like Hoyarn Grass offer extensive customization to meet unique project requirements:

- Color Variations: A wide palette of colors allows for creative designs, multi-zone play areas, and branded integrations.

- Pile Height & Density: Varying specifications to accommodate different critical fall heights, pedestrian traffic, or aesthetic preferences.

- Infill Systems: Selection of infill materials (e.g., crumb rubber, silica sand, organic infills) to meet specific safety, environmental, and thermal requirements.

- Integrated Designs: Cutting and inlaying different colored turf to create patterns, numbers, letters, or thematic designs.

Installation Considerations: How to Install Artificial Grass for Playground

Proper installation is as critical as turf quality. For comprehensive safety and longevity, understanding how to install artificial grass for playground involves:

- Site Preparation: Ensuring a stable, well-drained sub-base, often compacted aggregate, with appropriate grading for water runoff.

- Edging & Bordering: Securely establishing perimeter edges to contain infill and prevent turf lifting.

- Shock Pad Installation: For critical fall height compliance, installing a high-density, closed-cell foam shock pad beneath the turf.

- Turf Laying & Seaming: Carefully unrolling and cutting turf rolls, then precisely seaming them together using specialized adhesive and seaming tape.

- Infill Application: Uniformly spreading the specified infill material(s) and mechanically brushing it into the turf fibers to achieve the desired CFH and aesthetic.

Example of a custom artificial turf playground design.

Vendor Comparison and Total Cost of Ownership: Analyzing playground artificial turf price

When evaluating the playground artificial turf price, a holistic view of the total cost of ownership (TCO) is essential. Initial purchase price can be misleading without considering factors like material quality, warranty, maintenance, and expected lifespan. Below is a comparative analysis:

| Feature/Metric | Standard Vendor (Lower Initial Cost) | Hoyarn Grass (Premium, Long-Term Value) |

|---|---|---|

| Yarn Quality (Dtex) | Often < 8,000; mixed PE/PP or fibrillated. | 12,000+ Dtex monofilament PE with PP thatch. |

| UV Resistance (Hours) | < 3,000 hours (Grade 2-3). | > 6,000 hours (Grade 4-5, DIN 53387). |

| Backing Material | Single PP layer with lower-grade latex. | Double PP with high-grade SBR Latex or Polyurethane. |

| Critical Fall Height (CFH) Certification | Limited or vague; may require significant infill/shock pad. | ASTM F1292 certified up to 2.5m with optimized infill/shock pad. |

| Drainage Performance | Basic perforation, potential for pooling. | Engineered perforation for rapid drainage (80-100 L/min/m²). |

| Warranty | 5-8 years, often limited coverage. | 10-15 years, comprehensive coverage against manufacturing defects and excessive UV degradation. |

| Expected Lifespan | 8-10 years before significant degradation. | 15+ years with proper maintenance. |

| Total Cost of Ownership (TCO) | Lower initial playground artificial turf price, but higher replacement frequency and maintenance. | Higher initial playground artificial turf price, but significantly lower long-term costs due to durability, lower maintenance, and extended lifespan. |

While the initial playground artificial turf price from a premium vendor like Hoyarn Grass might appear higher, the superior product quality, extended warranty, reduced maintenance burden, and significantly longer lifespan translate into a lower total cost of ownership over the project's lifecycle. Investing in certified, high-performance turf minimizes future operational expenditures and ensures consistent safety and aesthetic appeal.

Example of turf quality differences evident in yarn and backing.

Application Case Studies & Customer Experience

Real-world implementations underscore the tangible benefits of high-quality artificial turf for playgrounds. Our experience with diverse clients highlights the transformative impact of the right surfacing solution:

Case Study 1: Municipal Park Revitalization (City of Greenview)

Challenge: An aging municipal park playground suffered from inconsistent natural grass, mud patches after rain, and high maintenance costs. Safety concerns arose from uneven surfaces around play equipment.

Solution: Installation of 1,500 sq/m of "Artificial Turf For Green Playgrounds, Boundless Energy" with a 2.0m CFH shock pad. Customized multi-colored zones were integrated to delineate play areas.

Outcome: A consistently safe, vibrant, and accessible playground year-round. The city reported a 70% reduction in water usage for the play area and a 60% decrease in overall maintenance labor. Public feedback cited improved aesthetics and enhanced safety as key benefits.

Case Study 2: Elementary School Playground Upgrade (Maplewood Academy)

Challenge: The school required a durable, low-allergen surface for its main playground, capable of supporting heavy student traffic and providing superior fall protection.

Solution: 1,200 sq/m of our premium artificial turf with a specific infill blend (silica sand and TPE granules) to meet 2.5m CFH requirements and minimize heat absorption. A custom school logo was incorporated into the design.

Outcome: The school now boasts an award-winning playground that is always ready for use, regardless of weather. Health records showed a noticeable decrease in playground-related minor injuries, and teachers praised the clean environment and reduced outdoor allergy triggers. The project demonstrated superior long-term value compared to recurring costs of traditional surfacing.

Children engaged in active play on a professionally installed artificial turf playground.

Trustworthiness & Support: Your Partner in Playground Solutions

Establishing trust and providing robust support are pillars of our commitment to B2B clients. We ensure transparency in all aspects, from product specifications to post-installation services.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a large-scale playground artificial turf order?

A: Standard lead times range from 3-5 weeks from order confirmation to shipment, depending on volume and customization requirements. Expedited options may be available upon request. Our fulfillment team coordinates logistics to ensure timely delivery.

Q: What are the warranty commitments for your artificial grass for playgrounds?

A: Our "Artificial Turf For Green Playgrounds, Boundless Energy" product comes with a comprehensive 10-year manufacturer's warranty covering significant UV degradation, excessive fading, and manufacturing defects. Specific terms and conditions are provided with each proposal.

Q: How do you ensure product safety compliance for critical fall heights?

A: All our playground turf systems are rigorously tested and certified to meet or exceed international safety standards, including ASTM F1292 (Impact Attenuation of Surfacing Materials) and ASTM F1951 (Accessibility of Surface Systems). We provide detailed test reports and recommendations for appropriate infill and shock pad configurations to achieve specified CFH ratings.

Q: What kind of after-sales support do you offer?

A: We offer extensive after-sales support including installation guidance, maintenance recommendations, and direct technical assistance. Our dedicated customer support team is available via phone and email to address any queries or concerns post-purchase and throughout the product's lifespan.

Conclusion: A Smart Investment in Safe, Sustainable Play

The decision regarding playground artificial turf price is not merely about initial expenditure but about a strategic long-term investment in safety, durability, and operational efficiency. By prioritizing high-quality materials, rigorous manufacturing processes, and adherence to stringent safety standards, entities can ensure their play environments are not only aesthetically pleasing but also consistently safe, accessible, and sustainable for years to come. Choosing a reputable provider with proven expertise and robust support ensures maximum value and peace of mind for B2B stakeholders.

References

- ASTM International. (2023). Standard Specification for Impact Attenuation of Surfacing Materials Within the Use Zone of Playground Equipment (ASTM F1292-23). West Conshohocken, PA.

- International Organization for Standardization. (2022). Quality management systems — Requirements (ISO 9001:2015). Geneva, Switzerland.

- The Synthetic Turf Council. (2023). Guidelines for Artificial Turf Installation and Maintenance in Playgrounds. Atlanta, GA.

- Journal of Environmental Management. (2021). "Lifecycle Assessment of Artificial Turf Systems for Public Playgrounds." Vol. 285, 112108.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories