Lush, Premium Quality Artificial Grass for Small Gardens & Balconies

Sep . 14, 2025 10:20 Back to list

Advancing Modern Landscapes with Premium Artificial Grass Solutions

In the rapidly evolving landscape of commercial and residential infrastructure, the demand for sustainable, low-maintenance, and aesthetically superior surfacing solutions is at an all-time high. Central to this demand is the rising adoption of quality artificial grass. This advanced material, far removed from its early iterations, now embodies cutting-edge polymer science and sophisticated manufacturing techniques, offering unparalleled durability, visual appeal, and ecological benefits. It represents a paradigm shift from traditional landscaping, providing a strategic advantage for businesses and homeowners seeking long-term value and reduced operational overhead. This article delves into the technical intricacies, application diversity, and strategic implications of integrating high-grade synthetic turf into modern design and construction projects.

Industry Trends & Market Dynamics in Artificial Grass

The global artificial grass market is experiencing robust growth, driven by escalating water scarcity, an increasing preference for low-maintenance landscaping, and innovations in product design. Projections indicate a compound annual growth rate (CAGR) of over 10% from 2023 to 2030, with market valuation expected to exceed $5 billion. Key trends include the integration of sustainable materials, enhanced UV stabilization for prolonged color retention, and advanced backing systems for superior drainage. There's a notable surge in demand from urban planning sectors for green spaces that require minimal resource input, such as rooftop gardens, public plazas, and medians. The residential segment also contributes significantly, with solutions tailored for compact spaces like a small astro turf garden or a small balcony garden with artificial grass. Manufacturers are increasingly focusing on Cradle-to-Cradle certified products and infill alternatives to address environmental concerns.

Manufacturing Process of Quality Artificial Grass

The production of high-performance artificial grass is a sophisticated multi-stage process, demanding precision engineering and stringent quality control. It begins with the selection of premium raw materials, primarily specialized polymer resins.

Materials & Components:

- Yarn Fibers: Predominantly Polyethylene (PE) for softness and resilience, Polypropylene (PP) for stiffness and durability (often used as thatch layer), and sometimes Nylon (PA) for extreme strength. These polymers are engineered with UV stabilizers to resist degradation from solar radiation and pigment additives for consistent color.

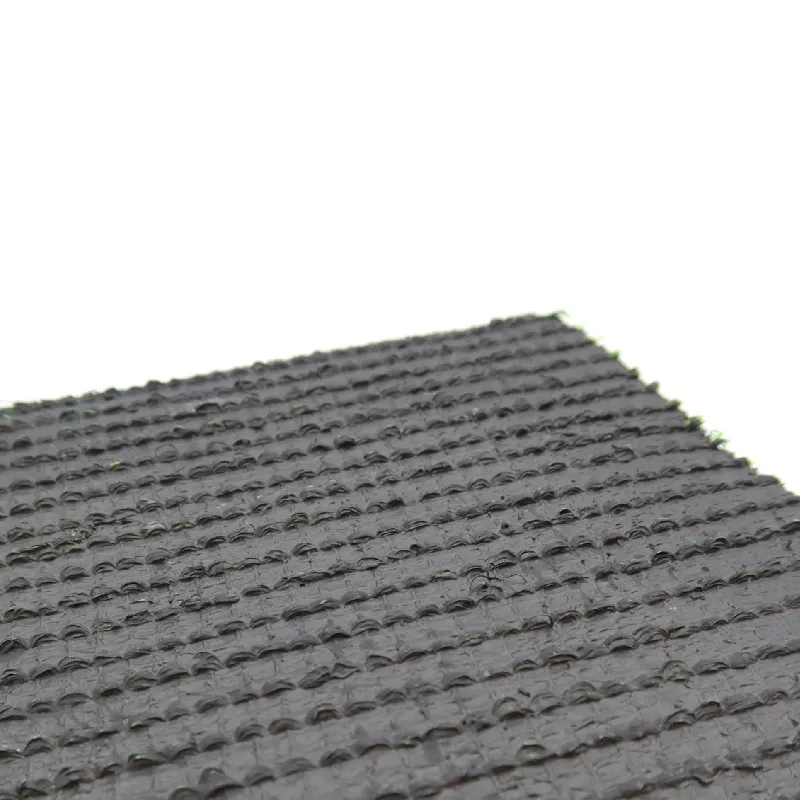

- Primary Backing: A woven polypropylene fabric that holds the tufted yarn in place and provides structural stability.

- Secondary Backing (Coating): A crucial layer, typically made from SBR latex or polyurethane. This coating locks the tufted fibers, enhancing dimensional stability, tuft bind, and overall longevity. Polyurethane offers superior adhesion, flexibility, and resistance to extreme temperatures and moisture.

- Infill: While not part of the manufacturing process, infill (e.g., silica sand, crumb rubber, or organic alternatives) is integral to the system's performance, providing ballast, cushioning, and support for the grass blades.

Manufacturing Stages:

- Extrusion (Yarn Production): Polymer pellets are melted and extruded through a die to form continuous filaments (yarns). These filaments are then textured, twisted, and heat-set to achieve the desired shape, resilience, and softness. Advanced extrusion techniques, similar to those in precision casting, ensure uniform filament thickness and strength.

- Tufting: Large industrial tufting machines, akin to large-scale textile looms, use multiple needles to stitch the yarn into the primary backing fabric in precise patterns and densities. This process determines the pile height, gauge, and stitch rate.

- Coating & Curing: The tufted fabric proceeds to a coating line where the liquid latex or polyurethane compound is applied to the underside of the primary backing. This material penetrates the backing, encapsulating the base of the yarn fibers to create a robust tuft bind. The coated turf then passes through ovens for high-temperature curing, ensuring the coating hardens and permanently locks the fibers.

- Perforation & Finishing: Small drainage holes are punched into the backing to facilitate water runoff. The turf is then trimmed to specified widths, inspected for quality, rolled, and packaged for shipment.

Testing Standards & Service Life:

To ensure superior performance and longevity, manufactured turf undergoes rigorous testing against international standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), CE Marking (European conformity), DIN (German Institute for Standardization), ASTM (American Society for Testing and Materials), and EN (European Standards). Tests cover UV stability (critical for color fastness), wear resistance (LISPORT test), pile bind strength, heavy metal content, flammability, and permeability. A premium quality artificial grass product, manufactured under these stringent protocols, typically offers a service life of 8-15 years, significantly reducing lifecycle costs compared to natural lawns.

Target Industries & Advantages:

These advanced artificial turf solutions are vital for sectors like commercial landscaping, hospitality, sports facilities, municipal parks, and residential developments. Advantages in typical application scenarios include significant energy saving due to elimination of mowing and irrigation equipment, and exceptional corrosion resistance as no pesticides, herbicides, or chemical fertilizers are required.

Technical Specifications & Parameters

Understanding the technical parameters is crucial for selecting the optimal artificial grass solution for specific project requirements. Below is a table outlining typical specifications for a high-quality artificial lawn product, such as "Natural Decorations: Artificial Lawn For Home."

Diverse Application Scenarios

The versatility of premium artificial grass allows its deployment across a wide spectrum of applications, from expansive commercial properties to intimate personal spaces. Its adaptability makes it an ideal solution where traditional natural grass presents logistical, maintenance, or environmental challenges.

- Commercial & Public Spaces: Corporate campuses, hospitality venues, retail storefronts, urban parks, and municipal greenbelts benefit from consistent aesthetics, minimal water usage, and reduced landscaping costs. The material's resilience ensures it withstands heavy foot traffic, maintaining its pristine appearance without the need for constant care.

- Residential Enhancement: From transforming entire backyards into lush, evergreen spaces to creating a charming small astro turf garden or an inviting small balcony garden with artificial grass, synthetic turf offers homeowners beauty without the burden. It's particularly favored in regions facing drought restrictions or for pet-friendly installations where natural grass struggles.

- Specialized Applications: Rooftop gardens benefit from its lightweight nature and excellent drainage properties. Indoor landscaping, exhibition spaces, and event venues leverage its consistent appearance and ease of installation. Even niche sports like mini-golf or bocce ball courts utilize artificial grass for consistent playability and reduced upkeep.

In scenarios such as large corporate parks, the elimination of irrigation systems and weekly mowing translates directly into significant energy saving, reducing operational expenditures and carbon footprint. Furthermore, the inherent inertness of the synthetic fibers ensures corrosion resistance against environmental factors and urban pollutants, maintaining visual integrity over years without degradation.

Technical Advantages of Quality Artificial Grass

The advanced engineering and material science behind modern artificial grass confer a multitude of technical advantages that make it a superior choice for discerning B2B clients and demanding projects.

- Exceptional Durability and Resilience: High-grade synthetic fibers, primarily PE with a PP thatch, are engineered for optimal rebound memory and resistance to matting. Coupled with advanced UV stabilization, the turf maintains its vibrant color and structural integrity for over a decade, even in harsh climates. Rigorous LISPORT testing confirms its ability to withstand intense foot traffic and environmental stress without significant degradation.

- Minimal Maintenance Requirements: The intrinsic nature of artificial turf eliminates the need for watering, mowing, fertilizing, or pest control. This significantly reduces operational costs, water consumption (up to 70% savings), and the environmental impact associated with traditional landscaping, offering a substantial return on investment.

- Superior Drainage and Hygiene: Perforated backing systems ensure rapid and efficient water runoff (typically >1,000 mm/hr/m²), preventing puddling and promoting a drier surface. This also makes the area more hygienic by deterring mold growth and facilitating easy cleaning, particularly beneficial for pet-friendly installations. Products compliant with REACH and RoHS standards ensure they are free from harmful heavy metals.

- Consistent Aesthetic Appeal: Unlike natural grass which is susceptible to seasonal changes, drought, and wear patterns, artificial turf provides a perfectly manicured, evergreen appearance year-round, irrespective of weather conditions. This consistency is invaluable for commercial properties aiming to maintain a professional and inviting exterior.

- Environmental Stewardship: Beyond water conservation, synthetic grass reduces reliance on fossil fuels for mowing, eliminates chemical runoff from fertilizers and pesticides, and can often be recycled at the end of its life cycle, aligning with corporate sustainability objectives.

Vendor Comparison: Value Proposition in Artificial Turf

When selecting a supplier for quality artificial grass, discerning buyers understand that initial cost is only one factor in the total cost of ownership. A comprehensive evaluation of material quality, manufacturing precision, and long-term performance is paramount. The table below illustrates a comparative analysis between a premium provider (reflecting the standards of Natural Decorations: Artificial Lawn For Home) and a standard market offering.

This comparison highlights that investing in a premium product offers superior longevity, performance, and overall value, ultimately translating into lower total cost of ownership and enhanced aesthetic integrity for any commercial or residential project.

Customized Solutions for Unique Project Demands

Recognizing that no two projects are identical, leading manufacturers of quality artificial grass offer comprehensive customization capabilities. This ensures that the aesthetic and functional requirements of any installation, from large-scale municipal projects to a bespoke small balcony garden with artificial grass, are met with precision.

- Pile Height and Density: Customization of pile height (e.g., 20mm for high-traffic, 40mm for lush aesthetics) and stitch density impacts both the visual appeal and the resilience of the turf. Lower pile heights are often chosen for pet areas or putting greens, while higher densities are ideal for luxurious landscape applications.

- Yarn Fiber Blend & Color: The ratio of PE to PP, and the specific Dtex of each fiber, can be adjusted to achieve desired softness, resilience, and realistic thatch effects. Custom color blends can mimic regional grass varieties or integrate corporate branding colors for unique designs.

- Backing Material: While standard offerings include SBR latex, projects requiring enhanced environmental resilience, superior tuft bind, or extreme temperature stability can opt for advanced polyurethane (PU) backing. PU backing provides better adhesion, is non-absorbent, and offers superior dimensional stability.

- Infill Optimization: Specialized infill materials, beyond basic silica sand, can be recommended or supplied. Options include cryogenic crumb rubber for sports fields, anti-microbial infills for pet areas, or organic infills for enhanced cooling and eco-friendliness.

These tailored solutions ensure that whether the objective is to create a vibrant play area, a low-maintenance corporate facade, or an elegant small astro turf garden, the artificial grass product is perfectly aligned with the project's functional and aesthetic specifications.

Application Case Studies: Proven Success

The tangible benefits of high-grade artificial turf are best demonstrated through real-world applications where it has provided effective, sustainable, and aesthetically pleasing solutions.

Case Study 1: Corporate Campus Modernization

A multinational technology firm sought to overhaul its 5-acre corporate campus landscaping to reduce water consumption and maintenance costs while maintaining a pristine, professional appearance year-round. After extensive evaluation, a premium quality artificial grass with a 40mm pile height and high-density PE yarn was selected.

- Outcome: Achieved a verifiable 65% reduction in annual water usage for landscaping, saving an estimated $75,000 annually. Labor costs for mowing and fertilizing were virtually eliminated. The campus now presents a consistently vibrant, manicured aesthetic, enhancing employee morale and corporate image.

Case Study 2: Urban Residential Development with Small Spaces

A new urban residential complex in a water-stressed region aimed to provide attractive outdoor spaces for residents, including small private gardens and communal leisure areas. The challenge was to create green, usable spaces without the high demands of natural turf. Customizable options allowed for the installation of numerous small astro turf garden units and a central pet-friendly area.

- Outcome: Residents now enjoy lush, green private patios and a clean, safe pet relief area with excellent drainage. The property management reports minimal maintenance requirements and high resident satisfaction due to the year-round usability and aesthetic appeal, even in a compact urban footprint.

Case Study 3: High-Rise Balcony Transformations

A luxury high-rise apartment building implemented artificial grass for its private balconies and communal rooftop terrace to provide a green oasis for residents without the weight or irrigation concerns of real turf. The lighter weight and custom cut sizes of artificial turf were critical.

- Outcome: Every apartment's balcony became a vibrant small balcony garden with artificial grass, adding significant value and appeal. The rooftop terrace became a popular amenity, providing a durable, attractive, and low-maintenance green space. The building experienced no drainage issues or structural concerns due to the lightweight nature and excellent permeability of the chosen turf.

Commitment to Trustworthiness: FAQ, Lead Time, Warranty & Support

Establishing long-term partnerships in the B2B sector hinges on transparency, reliability, and robust support systems. Our commitment to delivering high-performance quality artificial grass extends beyond the product itself to encompass comprehensive service.

Frequently Asked Questions (FAQ):

- Q: Is artificial grass safe for children and pets?

- A: Absolutely. Our products are REACH and RoHS compliant, ensuring they are free from heavy metals and harmful chemicals. The excellent drainage properties also prevent standing water, reducing pest breeding grounds. Many of our solutions are specifically designed for pet-friendly installations.

- Q: How does artificial grass handle extreme weather?

- A: Engineered with advanced UV inhibitors, our turf resists fading and degradation from intense sun. Its robust backing systems ensure stability in fluctuating temperatures and efficient drainage prevents damage from heavy rainfall or snowmelt.

- Q: What is the expected lifespan of your artificial grass?

- A: With proper installation and minimal maintenance, our premium products typically last between 8 to 15 years, significantly outperforming conventional landscaping materials in terms of durability and aesthetic retention.

Lead Time & Fulfillment:

We operate with efficient supply chain logistics to ensure timely delivery. Standard orders typically have a lead time of 2-4 weeks from order confirmation, depending on volume and customization. For large-scale projects or specialized requirements, detailed production and delivery schedules are provided upfront, ensuring project timelines are met with precision. Global shipping capabilities are available, optimized for cost and speed.

Warranty Commitments:

All our premium artificial grass products are backed by an industry-leading 8-year limited manufacturer's warranty. This warranty covers manufacturing defects, significant UV degradation (excessive fading), and abnormal product deterioration under normal use conditions, providing peace of mind for your investment. Specific warranty terms are provided with each product quotation.

Customer Support:

Our dedicated technical support team is available to assist with product selection, installation guidance, and post-sales inquiries. We provide comprehensive documentation, including technical data sheets, installation manuals, and maintenance guidelines. For complex projects, on-site consultation and training can be arranged to ensure optimal project execution and long-term performance.

Conclusion

The evolution of artificial grass has culminated in a sophisticated product that offers compelling advantages across diverse B2B applications. From rigorous manufacturing processes and adherence to international testing standards to its ecological benefits and proven long-term performance, investing in quality artificial grass represents a strategic decision. It delivers not only aesthetic superiority and reduced maintenance burdens but also contributes positively to environmental sustainability and operational efficiency. For businesses and developers seeking durable, versatile, and cost-effective landscaping solutions, modern synthetic turf stands as an undeniable leader, transforming how we approach green spaces in an ever-urbanizing world.

References

- Market Analysis Report: Global Artificial Grass Market Size & Share. Grand View Research, Inc.

- Environmental Benefits of Artificial Turf. Synthetic Turf Council.

- ASTM International Standard F1551-09: Standard Test Methods for Comprehensive Characterization of Synthetic Turf Systems.

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- The Impact of Synthetic Turf on Water Conservation. United States Environmental Protection Agency.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories