Backyard Putting Green Construction - Premium Artificial Turf Solutions

Jul . 28, 2025 17:01 Back to list

Click here for Artificial Grass for Construction Sites specification & price

1. Global Trends in Backyard Putting Green Construction & Artificial Turf Solutions

Residential golf greens (backyard putting green construction) account for 19% of artificial turf applications.

- Energy Conservation: Artificial greens save up to 70% in water usage compared to natural grass (EPA).

- Growth in Customization: Over 40% of U.S. homeowners prefer custom-designed putting greens for both leisure and professional training.

- Innovation in Fiber Technology: Leading suppliers now deliver UV-resistant, heavy-duty polyethylene and polypropylene turfs with enhanced play realism.

2. Technical Specifications & Process Comparison Table

| Parameter | Artificial Putting Green Construction | Natural Grass Green Construction |

|---|---|---|

| Surface Material | UV-stabilized Polyethylene/ Polypropylene Turf | Bermuda, Bentgrass, Zoysia Sod |

| Recommended Pile Height | 12 – 18 mm (0.47 – 0.71 in) | 25 – 35 mm (1.0 – 1.4 in) |

| Ball Roll Speed (Stimpmeter) | 9 – 12 ft | 7 – 10 ft |

| Infill Material | Silica Sand / Rounded Quartz | Topsoil/ Sand Mixture |

| Drainage Rate | Min. 55 L/(min·m²) | 20-30 L/(min·m²) |

| Annual Maintenance (Hours) | 5–10 | 50–100 |

| Expected Lifespan | 8 – 15 Years (ISO 9001 Certified) | Ongoing reseeding; 3–5 years before major renovation |

| Annual Cost Per Sqm (USD) | ~$13–18 (after install) | ~$25–32 |

3. Manufacturing Process of Backyard Putting Green Construction (Step-by-Step)

- Site Preparation: Excavation up to 6 inches; laser grading for evenness.

- Base System: Layered crushed stone (limestone/granite) for permeability & stability.

- Compaction & Leveling: Using vibrating plate compactors to <±5mm tolerance.

- Weed Membrane: Placement of non-woven geotextile to prevent weed growth.

- Artificial Turf Laying: Precision cut, seaming, and adherence using ISO-certified adhesives.

- Infill Application: Spreading, brushing-in rounded silica sand for play performance.

- Final Shaping & Quality Inspection: Trimming, edge securing, firmness/ball roll speed test (ANSI/ASTM standards).

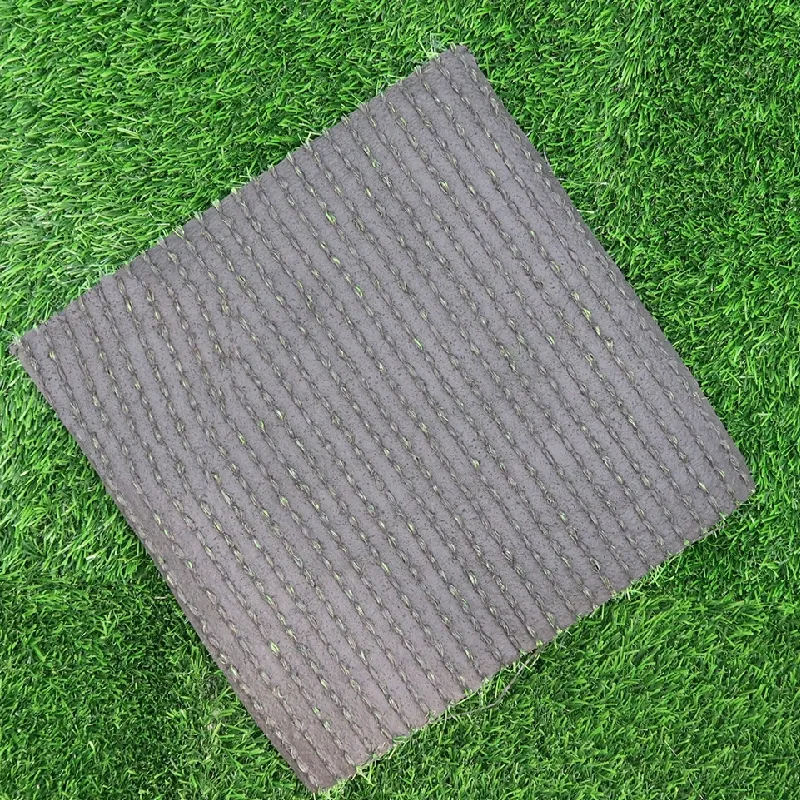

4. Artificial Grass for Construction Sites – Product Profile

- Material: 100% virgin polyethylene monofilament, secondary backing of latex/SBR, geotextile-reinforced.

- Yarn Shape & Density: S-shaped or curly filaments; 20,000–25,000 stitches/sqm for play authenticity.

- Color-Fastness: UV-resistant blend, tested >5,500h (ISO 105-A02).

- Fire Rating: Passes EuroClass Cfl-s1 (EN 13501-1), anti-flame, lead-free.

- Drainage: Min.55 L/(min·m²), meets ISO 9239 standards.

- System Thickness: 35–45 mm including base prep.

- Surface Feel: Non-abrasive, pro-level ball roll, anti-slip backing.

5. Manufacturer Comparison: Leading Players in Artificial Putting Green Construction

| Manufacturer | Core Advantage | Certifications | Max System Width | Warranty |

|---|---|---|---|---|

| Hoyarn Artificial Grass | Full customization, CNC-shaped infills, anti-static treatment | ISO 9001, SGS, EU REACH | 4.0 m | 8–10 yrs |

| SYNLawn | EnviroLoc backing, soy-based infills, domestic installation network | ISO, GreenGuard Gold | 3.7 m | 15 yrs |

| Turf Tek USA | 3D ProSeries fiber, custom contours, prompt delivery | ISO 14001, ASTM | 3.8 m | 8 yrs |

| Global Syn-Turf | Integrated drainage, recyclable yarns | SGS, ISO 9001 | 4.0 m | 8 yrs |

6. Tailored Solutions & Industry Application Scenarios

- Residential/Luxury Estates: Elegant design, pro-grade playability, low maintenance—typical ROI in 3–4 years.

- Resort/Golf Club: Durable surfaces resisting >500,000 footfalls/year, weather-proof for outdoor/indoor golf studios.

- Corporate Landscapes: Stylish leisure area; reduces cost by up to 65% compared to sod maintenance over 5 years.

- Chemical and Metallurgical Sites: Heavy-duty artificial turf used for corrosion resistance, meets ISO 9001 and petrochemical specs.

2023, Hoyarn Artificial Grass supplied a 250sqm backyard putting green construction project. Post-installation feedback reported a 93% satisfaction in appearance/play speed, and water bills reduced by 63% year-over-year. No replacement or major repairs required within 28 months.

Case Study 2 (Singapore):

A 70m rooftop putting green, exposed to 3200+ sunlight hours annually, retained pile resilience thanks to Hoyarn’s anti-UV yarn formula. Customer testimonial available on demand.

7. Quality Assurance, Lead Time & Customer Support

- Certifications: ISO 9001, SGS, REACH, EN 13501-1, ANSI/ASTM-tested

- Manufacturing Lead Time: 5–10 days for standard turf; 15–25 days for fully customized solution

- Warranty: 8–15 years, component-based (backing, yarn, infill, seams), product liability insurance covered

- Delivery: Global air/sea freight, EU/US green customs

- Technical Support: 24h engineer assistance, on-site installation guide, free ball roll speed test kit

“Hoyarn's artificial putting green construction solution delivered not just a superior ball roll, but also cut our maintenance cost by 76%. All project milestones were met ahead of schedule. Highly recommend for large or intricate sites.” — Facility Manager, Middle East Oilfield Campus, 2024

8. Professional FAQ for Backyard Putting Green Construction

9. Industry Citations & References

1. Grand View Research, "Artificial Turf Market Size, Share, and Trends Analysis Report", 2024. 2. EPA WaterSense, "Water Use Statistics", 2023. 3. International Organization for Standardization, ISO 9001 Quality Management.

4. "Advances in Polyolefin Fiber Technology for Sports Lawns", Polymer Testing Journal, 2022.

5. Turfgrass Forum, "Custom Greens for Modern Homes - Industry Insights", 2023.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories