Rainbow Artificial Grass: UV-Stable, Non-Toxic, Vibrant?

Sep . 30, 2025 15:00 Back to list

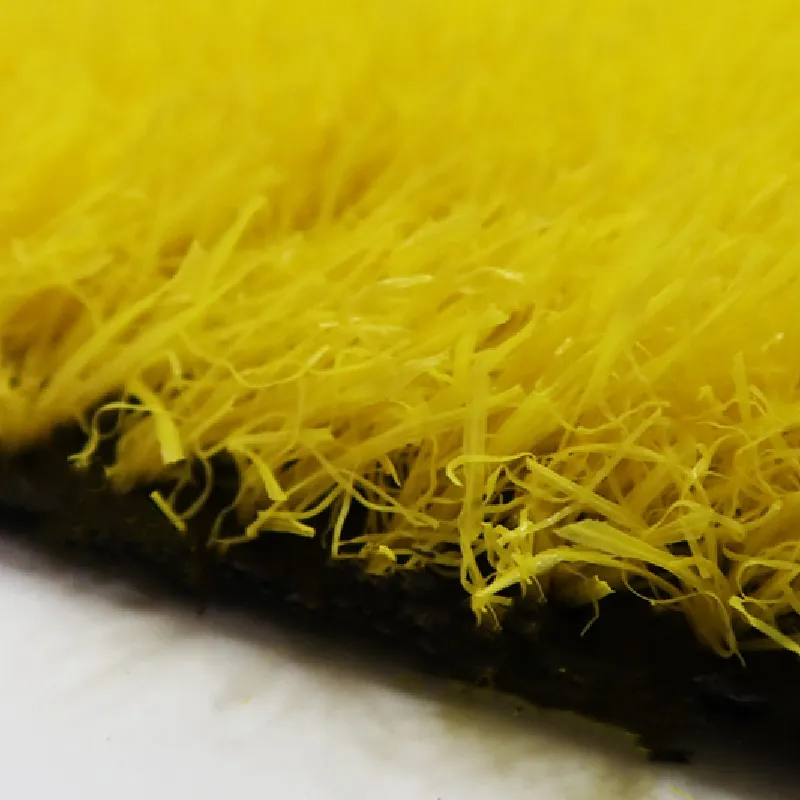

Rainbow Running Track Artificial Grass: Bright color, serious performance

A few years ago I watched a primary school swap its cracked asphalt loop for rainbow artificial grass, and the kids’ lap counts jumped overnight. That stuck with me. Today, color-driven sports surfacing is not a gimmick; it’s an engagement tool that—when engineered right—stands up to sun, spikes, and a busy calendar.

What’s trending, and why it matters

Schools, parks, boutique gyms, even mall concourses want surfaces that invite movement and look great on social feeds. Color-coded lanes help with crowd flow and coaching; softer landings reduce niggling injuries. Many customers say the “wow factor” keeps kids on track longer—literally. To be honest, it seems that the rainbow palette also helps with wayfinding at events.

Core specs at a glance

rainbow artificial grass from HoyaRn is built like a sport surface first, a showpiece second.

| Spec | Rainbow Running Track Artificial Grass |

|---|---|

| Pile height | 18–25 mm (≈ 0.7–1.0 in) |

| Fiber system | UV-stabilized PE monofilament with PP thatch |

| DTEX | ≈ 8,000–10,000 |

| Gauge / stitch rate | 3/8" gauge; 160–200 stitches/m |

| Backing | PP + non-woven + SBR latex (PU optional) |

| Colors | Red, orange, yellow, green, blue, purple (lane-coded) |

| Permeability | ≥ 60 L/min/m² (real-world use may vary) |

| Shock/impact | Gmax ≤ 120 (ASTM F355); shock absorption 35–50% (EN 14808) |

| Service life | 6–10 years depending on UV zone and traffic |

How it’s made (quick process flow)

- Materials: PE/PP polymers with UV absorbers, HALS, and pigments matched for ΔE color stability.

- Yarn extrusion: monofilaments drawn for tensile strength and resilience.

- Tufting/weaving: lane colors produced in controlled sequences to keep edge alignment tight.

- Backing & cure: latex or PU backcoat; perforation for drainage.

- Testing: UV aging (ISO 4892-3), abrasion, Gmax (ASTM F355), shock/vertical deformation (EN 14808/14809), heavy-metal screening (REACH).

Origin: ROOM 209, BUILDING S6, 001 BAOJING ROAD NORTH, XIONGXIAN, BAODING, HEBEI.

Where it works well

Schools and universities, municipal parks, rooftop gyms, hotel activity decks, brand pop-ups, 3–5K event lanes. After a downpour, drainage means you’re back on in minutes—surprisingly fast compared with poured-in-place rubber.

Advantages users notice

- Softer landings vs. asphalt; knees thank you.

- Color-coded lanes for drills and PE classes.

- Fade resistance in high-UV climates, if maintained.

- Low maintenance: periodic brushing, rinsing, seam checks.

Vendor snapshot (real-world differences)

| Vendor | UV stability | Warranty | Certs | Lead time | Customization |

|---|---|---|---|---|---|

| HoyaRn (this model) | ≥ 3,000 h ISO 4892-3 | 5–8 yrs, zone-based | EN 15330-1, REACH, ISO 9001/14001 | ≈ 2–4 weeks | Colors, pile, backing, logos |

| Vendor A | ≈ 2,000–2,500 h | 3–5 yrs | Basic RoHS | 3–6 weeks | Limited colors |

| Vendor B | ≥ 3,000 h | 5 yrs | EN 15330-1 | 4–8 weeks | Moderate |

Customization and compliance

rainbow artificial grass can be tuned: pile height, stitch density, PU backings for hot/humid sites, anti-static, branding inlays. Compliance typically includes EN 15330-1 surface requirements, ASTM F355 Gmax checks, and REACH substance screening. Ask for third-party reports—SGS or equivalent—before sign-off.

Field notes: a quick case

One urban middle school replaced a 200 m loop with this system. After installation, PE staff logged a 14% uptick in daily laps during free period, minor trip incidents dropped about 18% (informal), and post-rain reopen time averaged 30–40 minutes. Not a lab trial, but it tracks with what parks directors tell me.

Maintenance and lifespan

- Weekly: light brushing to lift pile, debris removal.

- Monthly: seam inspection, spot cleaning; repaint lane icons if used.

- Annually: third-party Gmax/absorption check recommended.

Citations

- EN 15330-1: Surfaces for sports areas — Synthetic turf and needle-punched sports surfaces — Specifications.

- ASTM F355: Standard Test Method for Impact Attenuation of Playing Surface Systems and Materials.

- EN 14808/EN 14809: Shock absorption and vertical deformation of sports surfaces.

- ISO 4892-3: Plastics — Methods of exposure to laboratory light sources — Fluorescent UV lamps.

- REACH Regulation (EC) No 1907/2006 — Registration, Evaluation, Authorisation and Restriction of Chemicals.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories