Playground Artificial Turf Price: Safe, Durable & Easy Installation

Aug . 31, 2025 05:00 Back to list

The Strategic Investment in Advanced Playground Surfacing

In modern urban planning and educational infrastructure, the choice of playground surfacing is paramount, balancing safety, durability, aesthetics, and cost-effectiveness. The market for high-performance artificial turf solutions is experiencing significant growth, driven by increasing demands for child safety and sustainable recreational spaces. Understanding the nuances of playground artificial turf price is essential for project managers, school administrators, and landscape architects seeking optimal value. This article delves into the technical aspects, market dynamics, and operational benefits of integrating premium artificial grass into play environments, ensuring a sound investment for long-term enjoyment and safety.

Industry Trends Shaping Playground Artificial Turf Adoption

The landscape of playground design is continuously evolving, with several key trends influencing the adoption of artificial turf. Foremost is the enhanced focus on safety, leading to stringent regulations and a preference for surfaces that offer superior fall attenuation. Artificial turf, especially when combined with shock-absorbing underlays, consistently meets or exceeds critical fall height (CFH) standards (e.g., ASTM F1292), significantly reducing injury risks compared to traditional surfaces like wood chips or sand.

Sustainability is another driving force. As water conservation becomes critical globally, artificial grass offers a substantial reduction in water usage, eliminating the need for irrigation associated with natural grass. Furthermore, advancements in material science are leading to the production of more eco-friendly turf products, incorporating recycled content and ensuring recyclability at the end of their service life. The demand for low-maintenance solutions also underpins turf's popularity, as it eliminates mowing, fertilizing, and pest control, resulting in long-term operational cost savings. Finally, the desire for all-weather playability ensures that playgrounds remain accessible and functional year-round, regardless of climatic conditions, making artificial grass an increasingly attractive option for modern recreational facilities.

Manufacturing Process: From Fiber to Field

The production of high-quality artificial turf involves a sophisticated, multi-stage manufacturing process, emphasizing material integrity and precision engineering. Understanding this process is key to appreciating the value proposition and the factors influencing playground artificial turf price.

Key Stages:

1. Fiber Extrusion

Materials: Primarily polyethylene (PE) or polypropylene (PP) pellets, chosen for durability, UV stability, and softness. Additives for UV resistance and color are compounded.

Process: Pellets are melted and extruded through a spinneret to form monofilament or fibrillated yarns. This process dictates the shape and strength of individual grass blades.

2. Yarn Twisting & Heat Setting

Process: Extruded yarns are twisted together to create bundles, enhancing resilience and upright memory. They are then heat-set to maintain their shape and prevent crimping. This critical step ensures the turf's long-term aesthetic and performance.

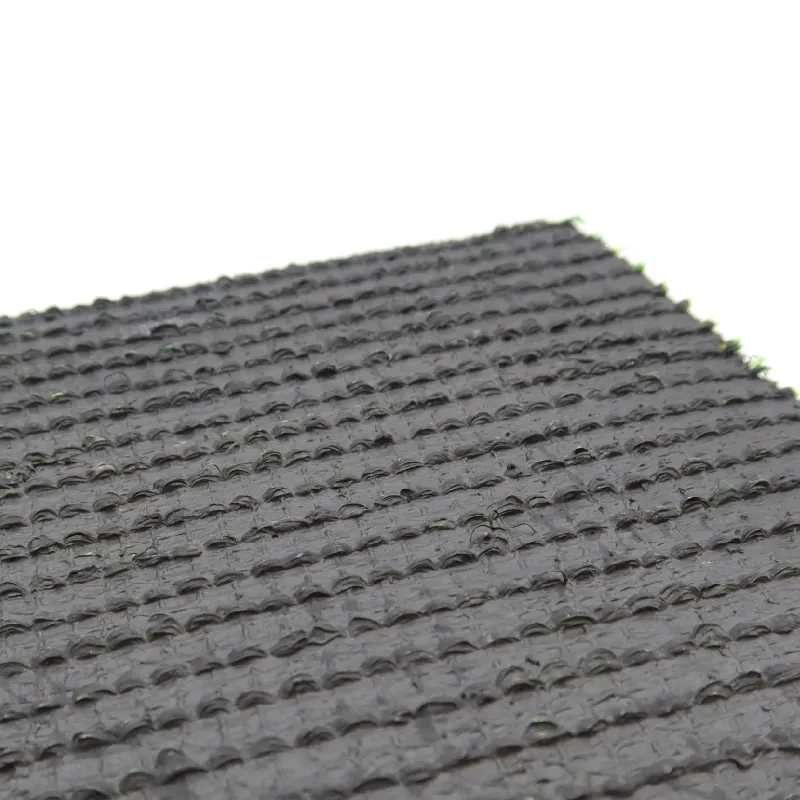

3. Tufting

Process: Yarns are fed into large tufting machines, which precisely stitch the fibers into a primary backing material (typically woven polypropylene). The "pile height" and "stitch rate" are defined here, impacting density and cushioning.

4. Coating & Curing

Materials: A secondary backing, often made of polyurethane (PU) or latex, is applied to the reverse side of the tufted turf.

Process: This coating securely locks the fibers in place, providing dimensional stability and enhancing durability. The material is then cured in an oven, a crucial step for bonding and longevity.

5. Finishing & Inspection

Process: The finished rolls are trimmed, slit, and meticulously inspected for quality control, ensuring consistency in color, pile height, and backing adhesion.

6. Packaging

Process: Rolls are carefully wrapped and prepared for shipment, often on specialized cores to prevent damage during transport.

Testing Standards & Service Life:

- Quality Management: ISO 9001 (quality management systems), ISO 14001 (environmental management systems).

- Safety: ASTM F1292 (Impact Attenuation of Playground Surfacing Systems), ASTM F1951 (Determination of Playground Surfacing Systems' Accessibility). European standards like EN 1177 are also crucial for critical fall height.

- Material Safety: REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), RoHS (Restriction of Hazardous Substances), ensuring non-toxic materials for child safety.

- Durability: UV stability (e.g., DIN 53387), wear resistance tests (e.g., Lisport XL), pull force tests for fiber anchorage.

- Typical Service Life: High-quality playground artificial turf is engineered for a service life of 8-15 years, depending on traffic, maintenance, and UV exposure.

Target Industries & Advantages:

This rigorous manufacturing process yields products suitable for a range of environments including:

- Educational Institutions: Schools, universities, daycare centers.

- Public & Municipal Spaces: City parks, community playgrounds, recreational facilities.

- Commercial & Residential: Theme parks, hotel play areas, private home playgrounds.

In these scenarios, artificial turf provides significant advantages:

- Water Conservation: Eliminates irrigation needs, saving millions of gallons annually compared to natural grass.

- Chemical Resistance: Resistant to common playground spills, cleaning agents, and pet waste, maintaining integrity and hygiene.

- UV Stability: Advanced polymers and UV inhibitors prevent degradation and fading, preserving aesthetic appeal over its extended service life.

- Enhanced Safety: Consistent impact absorption across the entire surface, providing uniform protection.

- Accessibility: Smooth, firm surface suitable for wheelchairs and strollers, meeting ADA compliance.

Technical Specifications and Product Parameters

Selecting the appropriate artificial turf for playground applications necessitates a thorough understanding of its technical specifications. These parameters directly influence performance, durability, safety, and ultimately, the long-term value of the investment, impacting the overall playground artificial turf price.

Product Specification: Artificial Turf For Green Playgrounds, Boundless Energy

Application Scenarios and Installation Considerations

Artificial grass for playgrounds offers unparalleled versatility, making it ideal for a multitude of application scenarios where safety, aesthetics, and low maintenance are paramount. Key areas include:

- Schools and Daycare Facilities: Providing safe, clean, and durable play surfaces for children of all ages.

- Public Parks and Municipal Playgrounds: Enhancing accessibility and ensuring year-round usability, reducing operational costs for local governments.

- Commercial Play Zones: Integrating visually appealing and safe turf into themed environments and entertainment centers.

- Residential Play Areas: Offering homeowners a premium, child-friendly backyard solution that stands up to heavy use.

Regarding how to install artificial grass for playground, the process typically involves several critical steps to ensure longevity and adherence to safety standards:

- Site Preparation: Clearing the area, ensuring proper drainage, and grading the sub-base for optimal water runoff.

- Base Layer Installation: Applying and compacting a permeable aggregate base (e.g., decomposed granite or crushed rock) to create a stable, level foundation.

- Shock Pad Installation: For playgrounds, a specialized shock-absorbing underlayment is crucial to meet Critical Fall Height requirements. These pads are laid directly on the compacted base.

- Turf Laying & Seaming: Rolls of artificial grass are unrolled, cut to fit, and meticulously seamed together using specialized adhesive and seaming tape.

- Infill Application: Applying an infill material (e.g., silica sand, rubber granules, or organic infill) to help the fibers stand upright, provide additional cushioning, and add ballast. The type and depth of infill directly impact safety performance.

- Final Grooming: Brushing the infill into the turf and grooming the fibers to create a natural, inviting appearance.

Proper installation is as vital as the quality of the turf itself for ensuring both safety and the investment's lifespan.

Technical Advantages of Artificial Grass for Playgrounds

The selection of artificial grass for playgrounds offers a compelling suite of technical advantages that extend beyond mere aesthetics, contributing to a superior and safer play environment.

- Superior Fall Protection: Engineered systems incorporating turf and shock pads provide consistent and predictable impact attenuation, crucial for preventing serious injuries from falls. Unlike loose-fill materials, turf maintains its protective qualities without constant raking or replenishment.

- All-Weather Playability & Rapid Drainage: Advanced backing systems ensure excellent permeability, allowing water to drain quickly, typically at rates exceeding 1000mm/hour per square meter. This means playgrounds remain dry and usable shortly after rain, minimizing downtime and maximizing play opportunities.

- Durability and Longevity: Manufactured from UV-stabilized polyolefins, the turf fibers are highly resistant to degradation from sunlight, extreme temperatures, and heavy foot traffic. The robust tuft-lock technology prevents fiber pull-out, ensuring the surface retains its integrity and density for many years.

- Low Maintenance & Cost Efficiency: Eliminates the need for mowing, watering, fertilizing, and pesticidal treatments. This significantly reduces ongoing labor and material costs, offering substantial savings over the lifespan of the turf compared to natural grass or other surfacing options.

- Hygienic and Allergen-Reduced: Artificial turf does not harbor common allergens like pollen or grass seeds. Its non-organic nature also reduces habitats for insects and pests, contributing to a cleaner and healthier play environment for children.

- Environmental Benefits: Significant water savings are a primary ecological advantage. Furthermore, modern turf products are often made with recyclable components and are designed for end-of-life recycling, reducing landfill waste.

- Consistent Aesthetics: Maintains a vibrant, green appearance year-round, regardless of climate, season, or usage intensity, enhancing the visual appeal of any play area.

Vendor Comparison and Selection Criteria

Navigating the market for artificial turf requires a meticulous approach to vendor comparison. The initial playground artificial turf price is just one component; factors such as product quality, manufacturing certifications, warranty, and customer support significantly influence the total cost of ownership and long-term satisfaction.

Key Comparison Parameters:

Partnering with a reputable manufacturer, like HOYARN GRASS, ensures access to products meeting rigorous international safety and quality standards, backed by reliable service and robust warranties. This minimizes risks and maximizes the return on investment for playground installations.

Customized Solutions for Unique Play Environments

Every playground has unique requirements, from specific aesthetic themes to varying critical fall height needs. Leading manufacturers offer comprehensive customization options to ensure the artificial turf solution perfectly aligns with project specifications.

- Pile Height and Density: Adjustable to meet specific comfort, safety (CFH), and aesthetic preferences. Shorter pile for high-traffic zones, longer for softer landings.

- Color Options: Beyond traditional green, turf can be manufactured in a spectrum of colors to create engaging patterns, incorporate school colors, or delineate play zones.

- Infill Solutions: Choices include antimicrobial silica sand, non-toxic rubber granules, or organic infills (e.g., coconut fiber), each offering different levels of cushioning, cooling, and antimicrobial properties.

- Shock Pad Systems: Various thicknesses and densities of foam or rubber shock pads can be specified to achieve precise critical fall height ratings for different play equipment.

- Integrated Graphics & Logos: Custom designs, games, and branding elements can be seamlessly integrated into the turf surface during installation, adding a unique and interactive dimension to the playground.

- Specialized Backings: Options like eco-friendly polyurethane backing for enhanced drainage and durability, or anti-static treatments for specific climates.

These tailored solutions ensure that each playground not only meets the strictest safety standards but also provides a visually stimulating and highly functional environment for children.

Application Case Studies

Real-world applications highlight the transformative impact of high-quality artificial turf in diverse playground settings.

Case Study 1: Urban School District Renovation

A major urban school district faced challenges with muddy, worn-out natural grass playgrounds that were often unusable after rain, leading to lost play opportunities and high maintenance costs. They partnered with a leading artificial turf provider to install "Artificial Turf For Green Playgrounds, Boundless Energy" across ten elementary school sites. The solution included a 50mm pile height turf combined with a 25mm high-density shock pad, achieving a CFH of 2.5 meters.

Results: Post-installation, the schools reported a 90% reduction in maintenance costs related to turf (no watering, mowing, or reseeding). Playgrounds became accessible immediately after rainfall, and parent feedback emphasized increased safety and cleanliness. The vibrant, green surfaces also enhanced the aesthetic appeal of the school campuses.

Case Study 2: Community Park Play Area Upgrade

A local municipality sought to upgrade a heavily trafficked community park playground, which frequently developed bare spots and drainage issues. They opted for artificial grass for playgrounds with a focus on extreme durability and ADA compliance. A customized installation featured multi-color turf sections defining different play zones, integrated with a rubber infill system.

Results: The new playground saw a significant increase in daily visitors. The durable turf withstood intense use without degradation, and the advanced drainage system eliminated previous pooling problems. The uniform, level surface greatly improved accessibility for children with disabilities, earning positive acclaim from the community.

Trustworthiness and Support for Your Investment

Frequently Asked Questions (FAQ)

A: High-quality artificial turf for playgrounds, such as Artificial Turf For Green Playgrounds, Boundless Energy, typically lasts 8 to 15 years, depending on traffic, maintenance, and environmental conditions. UV stability is key to this longevity.

A: Absolutely. Reputable manufacturers ensure their products comply with strict international standards like REACH and RoHS, certifying that the materials are non-toxic and free from heavy metals or harmful chemicals, making them safe for children.

A: Artificial turf systems, particularly those with perforated backing, offer superior drainage capabilities, often exceeding 1000mm per hour per square meter. This means playgrounds dry significantly faster than natural grass, allowing for immediate use after rainfall.

A: For standard orders, the lead time from order confirmation to shipment generally ranges from 3 to 4 weeks. Custom orders or large-scale projects may require slightly longer lead times, which are communicated clearly during the quotation phase.

Lead Time & Fulfillment

Our streamlined manufacturing and logistics ensure efficient order fulfillment. Standard artificial turf orders are typically processed and ready for shipment within 3-4 weeks. For large-scale projects or highly customized solutions, a detailed production schedule will be provided upon order confirmation, ensuring transparency and timely delivery. We work with trusted global shipping partners to facilitate reliable transportation to your project site.

Warranty Commitments

We stand by the quality of our "Artificial Turf For Green Playgrounds, Boundless Energy" with a robust warranty package. This typically includes an 8-10 year warranty against UV degradation and manufacturing defects, safeguarding your investment. Specific warranty terms will be provided with your project proposal, outlining coverage for material integrity and performance under normal usage conditions.

Customer Support

Our commitment extends beyond product delivery. We provide comprehensive after-sales support, including technical guidance for installation, maintenance recommendations, and prompt assistance for any product-related inquiries. Our dedicated customer service team is available to ensure your satisfaction and the longevity of your artificial turf playground.

Conclusion: A Sustainable and Safe Investment

The strategic decision to invest in high-quality playground artificial turf price is increasingly recognized by B2B decision-makers for its long-term benefits. From superior safety compliance and minimal maintenance to significant water conservation and year-round usability, advanced artificial grass solutions offer a compelling return on investment. By understanding the intricate manufacturing processes, adhering to rigorous technical specifications, and partnering with reputable vendors, organizations can create truly boundless and safe play environments that stand the test of time, both physically and environmentally. The transition to artificial turf represents not just an upgrade in surfacing, but a commitment to future-proof, sustainable, and high-performance recreational infrastructure.

References

- American Society for Testing and Materials (ASTM International) – F1292 Standard Specification for Impact Attenuation of Surfacing Materials Within the Use Zone of Playground Equipment.

- European Committee for Standardization (CEN) – EN 1177 Impact Attenuating Playground Surfacing – Test Methods to Determine Impact Attenuation.

- Synthetic Turf Council – "STC Guidelines for Artificial Turf Installation."

- National Recreation and Park Association (NRPA) – "Playground Safety Resources."

- Polyethylene Polymer Chemistry and Properties - ScienceDirect.

- International Organization for Standardization (ISO) – ISO 9001 Quality Management Systems & ISO 14001 Environmental Management Systems.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories