Playground Artificial Turf Price: Safe, Durable Solutions

Aug . 13, 2025 03:40 Back to list

Navigating the Landscape of Playground Artificial Turf Solutions

In an era where child safety and sustainable infrastructure are paramount, artificial turf has emerged as a superior alternative to traditional playground surfaces. Its rapid adoption is driven by unmatched durability, low maintenance, and critically, enhanced safety features. Understanding the playground artificial turf price is essential for municipalities, schools, and private developers seeking to invest in long-term, high-performance play areas. This comprehensive guide delves into the various facets influencing cost, material science, installation methodologies, and the tangible benefits of selecting premium synthetic surfacing like our Artificial Turf For Green Playgrounds, Boundless Energy, designed to foster boundless energy and safe play.

The demand for robust and aesthetically pleasing surfaces has led to significant advancements in artificial turf technology. Modern synthetic grass for playgrounds is engineered not only for visual appeal but also for critical safety standards, including impact absorption, UV stability, and optimal drainage. These technological improvements directly influence the overall investment, offering superior value over time compared to natural grass which requires constant irrigation, fertilization, and mowing. Our commitment at Hoyarn Grass is to provide solutions that meet stringent international safety norms, ensuring every play surface is a safe haven for children while offering exceptional longevity and resilience against heavy foot traffic and diverse weather conditions, thereby optimizing the long-term cost-effectiveness.

Factors Influencing Playground Artificial Turf Price

The upfront cost of synthetic turf for playgrounds is a multi-faceted calculation, influenced by several key parameters. Firstly, the material quality, specifically the fiber type (e.g., polyethylene, polypropylene, nylon), significantly impacts durability and feel. Higher-grade fibers offer enhanced resilience, UV resistance, and a more natural appearance, contributing to a higher initial investment but promising a longer lifespan and reduced maintenance over time. Pile height, which is the length of the grass blades, also plays a crucial role; taller piles generally use more material and provide greater cushioning, vital for playground safety. Another critical factor is the backing material, typically a multi-layered system designed for superior dimensional stability and robust drainage.

Beyond material composition, the density and stitch rate of the turf, referring to how closely packed the fibers are and how many stitches per square inch, directly affect the product's performance and cost. A higher density means more fibers per square foot, offering a plusher feel and increased wear resistance. Infill type, such as crumb rubber, silica sand, or organic infills, is also a critical consideration for safety and performance, influencing impact attenuation and temperature regulation. Finally, the complexity of the installation, site preparation requirements, and geographical location can all contribute to the overall project cost. Understanding these elements is paramount for a precise estimation of the total playground artificial turf price.

The Advanced Manufacturing Process of Artificial Turf

The creation of high-quality artificial grass for playgrounds involves a sophisticated multi-stage manufacturing process, ensuring durability, safety, and aesthetic appeal. It begins with the extrusion of polymer resins, typically polyethylene or polypropylene, into individual synthetic fibers. These fibers are engineered with specific denier (a unit of linear mass density of fibers, indicating their thickness and strength), color pigments, and UV stabilizers to resist fading and degradation from sunlight. Following extrusion, the fibers are twisted or crimped to mimic the natural look and feel of grass blades, enhancing their resilience and cushioning properties.

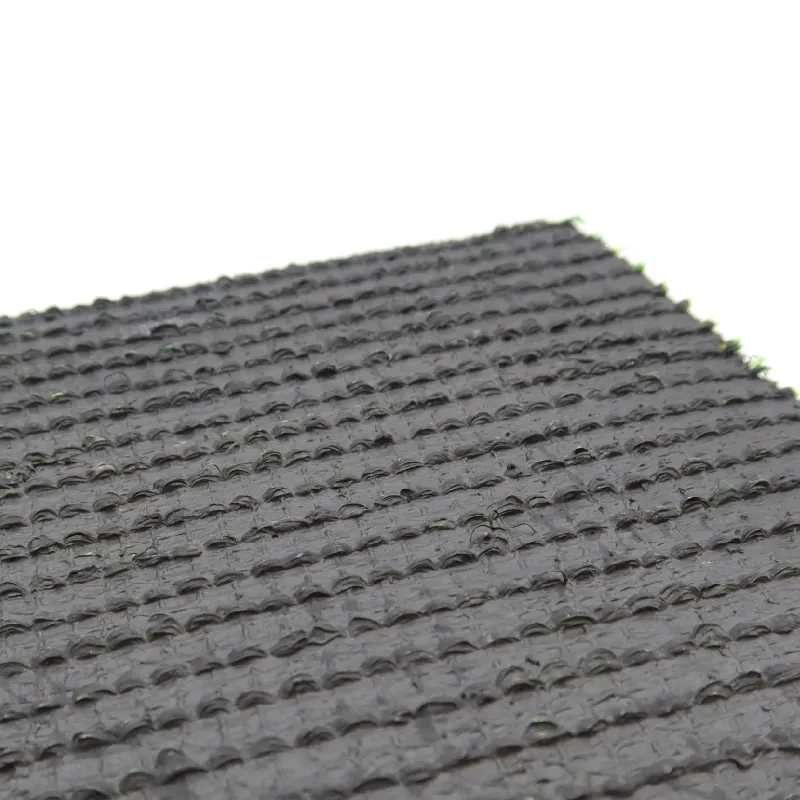

Next, these individual fibers are fed into large tufting machines, similar to carpet looms, which precisely stitch the fibers into a robust primary backing fabric, often made of woven polypropylene. The density of these stitches, known as the stitch rate or gauge, directly influences the turf's plushness and durability. After tufting, the primary backing, now with fibers attached, is coated with a secondary backing layer, usually made of latex or polyurethane. This coating securely locks the fibers in place, adds dimensional stability, and provides essential drainage perforations. Rigorous quality control checks, adhering to standards like ISO 9001, are conducted at each stage to ensure consistency, strength, and environmental compliance, guaranteeing that every roll of our Artificial Turf For Green Playgrounds meets the highest benchmarks before it even reaches the installation site.

Key Technical Parameters and Price Considerations for Playground Artificial Turf

When evaluating the playground artificial turf price, understanding the underlying technical specifications is crucial. These parameters directly correlate with the turf’s performance, longevity, and safety features. Pile height, for instance, typically ranges from 1.5 to 2.5 inches for playgrounds, with taller piles offering better cushioning for critical fall height compliance. Face weight, measured in ounces per square yard, indicates the amount of fiber used, directly impacting density and durability. A higher face weight generally translates to a more robust and resilient surface.

Draining capabilities are another vital aspect, measured by the permeability rate, ensuring efficient water runoff and preventing pooling after rain. UV resistance is critical for preventing color fading and material degradation under prolonged sun exposure, significantly extending the turf's lifespan. Shock absorption, often rated by Critical Fall Height (CFH) via ASTM F1292 testing, measures the maximum height from which a child can fall onto the surface without sustaining a life-threatening head injury, making it a non-negotiable parameter for playground applications. The table below outlines typical ranges and their impact on the overall investment for various types of artificial grass for playgrounds.

| Parameter | Description | Typical Range (Playground) | Price Impact (Relative) |

|---|---|---|---|

| Pile Height | Length of grass blades | 1.5" - 2.5" (38mm - 63mm) | Medium to High (More material, better fall protection) |

| Face Weight | Weight of turf fibers per square yard | 50 - 80 oz/sq.yd | High (More material, denser, more durable) |

| Backing Material | Primary and secondary backing layers | Polyurethane/Latex coated woven fabric | Medium to High (Critical for stability, drainage, longevity) |

| Infill System | Granular material brushed into turf fibers | Crumb Rubber, Silica Sand, Organic | Variable (Safety, temperature, stability) |

| Critical Fall Height (CFH) | Max height for safe fall (ASTM F1292) | 4ft - 12ft (1.2m - 3.6m) | High (Requires specific padding layers, impacts overall cost) |

| Warranty | Manufacturer's guarantee against defects | 8 - 15 years | Reflects quality, impacts long-term value |

Application Scenarios and Technical Advantages

Artificial turf for playgrounds is not merely an aesthetic choice; it’s a strategic investment in safety, sustainability, and operational efficiency across various sectors. Its primary application lies in school playgrounds, municipal parks, childcare centers, and residential play areas where consistent safety and year-round usability are paramount. Unlike natural grass, which can become muddy, uneven, or dusty, synthetic turf offers a consistently level and clean surface, significantly reducing the risk of slips, trips, and falls. The integrated drainage systems ensure playgrounds are ready for use shortly after rain, maximizing play time and minimizing operational delays.

Beyond safety, the technical advantages of high-quality artificial grass for playgrounds are substantial. Its exceptional durability means it can withstand heavy foot traffic, constant play, and diverse weather conditions without showing signs of wear and tear, leading to a much longer lifespan than natural alternatives. The UV stabilization ensures color integrity and material strength over years, even in harsh climates. Furthermore, the substantial reduction in water consumption for irrigation and the elimination of fertilizers, pesticides, and regular mowing represent significant long-term savings and environmental benefits. This leads to a lower total cost of ownership, making the initial playground artificial turf price a worthwhile long-term investment.

Mastering the Installation: How to Install Artificial Grass for Playground

The successful implementation of artificial turf for playground safety and longevity heavily relies on a professional and meticulous installation process. While the specific steps for how to install artificial grass for playground can vary based on site conditions and turf system, the general procedure follows a structured approach. Firstly, proper site preparation is paramount, involving the removal of existing vegetation and leveling the ground to ensure adequate drainage. An aggregate base layer, typically compacted crushed rock, is then installed to provide a stable, permeable foundation. This layer is critical for consistent surface performance and efficient water runoff.

For playgrounds, an additional shock-absorbent underlayment, often made of foam padding or recycled rubber, is installed directly over the base layer. This layer is crucial for meeting Critical Fall Height (CFH) requirements, significantly enhancing child safety. Once the padding is in place, the artificial turf rolls are carefully laid out, trimmed to fit the contours of the play area, and seamlessly joined using specialized seaming tape and adhesive. Finally, an infill material is evenly distributed and brushed into the turf fibers. This infill helps the blades stand upright, provides additional cushioning, and stabilizes the system. Proper installation ensures the turf performs optimally, maintaining its safety features and aesthetic appeal for its extensive lifespan, making the initial playground artificial turf price a sound investment.

Ensuring Quality and Longevity: Certifications and Testing

The credibility and long-term performance of artificial turf for playgrounds are rigorously validated through adherence to international standards and comprehensive testing protocols. For instance, our Artificial Turf For Green Playgrounds, Boundless Energy, undergoes stringent evaluations to meet benchmarks such as ASTM F1292, which assesses impact attenuation of surfacing materials within the use zone of playground equipment. This certification is crucial for verifying the critical fall height capabilities, directly addressing safety concerns for children at play. Similarly, compliance with EN 1177 (Impact Attenuating Playground Surfacing) is often required in European markets, ensuring a global standard of safety is met.

Beyond safety, material durability and environmental impact are also tested. UV stability is assessed to ensure the turf retains its color and structural integrity under prolonged sun exposure, while heavy metal content analysis (e.g., California Prop 65, EN 71-3) guarantees non-toxicity, making the surface safe for children. Our manufacturing processes are also certified under ISO 9001 for quality management systems, demonstrating a consistent commitment to excellence in production. These certifications and regular third-party testing provide concrete evidence of our product's superior quality, performance, and safety, reassuring stakeholders that their investment in playground artificial turf price delivers unparalleled value and peace of mind.

Trust and Reliability: FAQ, Warranty, and Support

Investing in artificial turf for playgrounds is a significant decision, and trust in the supplier is paramount. We understand that prospective clients have critical questions regarding long-term performance, safety, and maintenance. Our commitment extends beyond the initial sale, providing comprehensive support throughout the product's lifecycle. We offer robust warranties, typically ranging from 8 to 15 years, covering manufacturing defects and significant UV degradation, providing reassurance for your investment in playground artificial turf price. Our delivery cycles are optimized for efficiency, typically ranging from 4-6 weeks for custom orders, with transparent tracking and dedicated logistics support to ensure timely project completion.

Our dedicated customer support team is available to address any inquiries, from product selection to post-installation care. Below are some frequently asked questions (FAQs) to further assist you:

- Q: Is artificial turf for playgrounds truly safe for children?

A: Absolutely. Our turf products, especially Artificial Turf For Green Playgrounds, are engineered with critical fall height ratings and non-toxic materials, certified by independent testing bodies like ASTM F1292 and EN 71-3, ensuring a safe play environment. - Q: How does the turf handle drainage?

A: Our turf features advanced backing with permeable perforations, allowing for excellent vertical drainage. This design ensures that playgrounds dry quickly after rain, preventing standing water and minimizing downtime. - Q: What is the expected lifespan of your artificial grass for playgrounds?

A: With proper installation and minimal maintenance, our playground turf is designed to last 10-15 years, offering a highly durable and long-lasting surface that retains its aesthetic appeal and safety features. - Q: What maintenance is required?

A: Compared to natural grass, maintenance is minimal. It primarily involves occasional rinsing to remove dust, brushing to keep fibers upright, and removing debris. No watering, mowing, or fertilizing is needed.

Our commitment to quality, backed by rigorous testing and comprehensive support, ensures that every investment in our artificial turf solutions provides lasting value and peace of mind.

Conclusion: A Smart Investment in Play Infrastructure

The decision to invest in artificial turf for playgrounds represents a forward-thinking approach to urban and educational infrastructure development. While the initial playground artificial turf price may appear higher than traditional grass, the long-term benefits in terms of safety, durability, reduced maintenance, and environmental sustainability far outweigh the upfront costs. Our Artificial Turf For Green Playgrounds, Boundless Energy, is a testament to cutting-edge technology and a commitment to creating safe, vibrant, and sustainable play spaces for the next generation. By understanding the intricate manufacturing processes, key technical parameters, and the comprehensive support we provide, stakeholders can make informed decisions that ensure optimal value and performance for years to come.

We invite you to explore the possibilities of transforming your play areas into zones of boundless energy, where safety and environmental responsibility go hand-in-hand. For detailed consultations and customized solutions tailored to your specific project needs, please visit our product page or contact our expert team.

References:

- American Society for Testing and Materials (ASTM) F1292. Standard Specification for Impact Attenuation of Surfacing Materials Within the Use Zone of Playground Equipment.

- European Committee for Standardization (CEN) EN 1177. Impact attenuating playground surfacing – Determination of critical fall height.

- International Organization for Standardization (ISO) 9001. Quality management systems – Requirements.

- Artificial Turf Council. (2023). Benefits of Artificial Turf.

- Environmental Protection Agency (EPA). (2019). Artificial Turf Fields: Health and Safety.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories