Expert Backyard Putting Green Construction | Free Quote

Aug . 06, 2025 07:40 Back to list

Transform your backyard into a golfer's paradise. This comprehensive guide delves into the technology, materials, and expert processes behind high-performance backyard putting green construction, setting a new standard for home recreation.

Achieve a tour-quality green right in your own backyard with professional artificial turf construction.

The Green Revolution: Why Home Putting Greens are on the Rise

The demand for sophisticated home amenities has surged, and for golf enthusiasts, nothing adds more value and enjoyment than a personal putting green. The global artificial turf market is projected to reach USD 5.8 billion by 2028, growing at a CAGR of 6.5%, with a significant portion driven by residential landscaping and recreation. This trend underscores a shift away from high-maintenance natural grass to advanced, durable, and realistic artificial surfaces. A professional backyard putting green construction is no longer just a luxury; it's an investment in lifestyle, property value, and your golf game.

Modern artificial putting green construction leverages cutting-edge material science and installation techniques to replicate the performance of top-tier golf courses. Unlike the astroturf of the past, today's products, like those from HoyarnGrass, offer true ball roll, realistic speeds, and all-weather durability, making them the superior choice for discerning homeowners.

Understanding the Core Components: The Science Behind the Surface

The success of a backyard putting green construction project hinges on a deep understanding of its technical components. It's a multi-layered system where each element plays a critical role in performance and longevity.

The fiber density and material composition are crucial for realistic ball roll.

1. Turf Fiber Technology: More Than Just Plastic

The putting surface itself is a marvel of polymer science. The primary materials used are:

- Polyethylene (PE): The preferred choice for modern putting greens. PE fibers are soft, non-abrasive, and offer excellent resilience, providing a realistic feel and consistent performance. HoyarnGrass utilizes 100% C6 DOW-imported PE for superior UV stability and durability.

- Polypropylene (PP): A slightly stiffer fiber, often used for fringe grass or older-style, faster greens. While durable, it can be more abrasive than PE.

- Nylon: The most resilient and expensive option. Nylon can withstand heavy traffic and heat but is often considered too fast and less realistic for putting unless blended with PE.

2. Critical Turf Specifications Explained

When evaluating turf for artificial putting green construction, several key metrics determine its quality and performance:

- Pile Height: For putting greens, a low pile height (typically 12-18mm) is essential for a smooth, fast ball roll.

- Face Weight: Measured in ounces per square yard, this indicates the amount of yarn used in the turf. A higher face weight (e.g., 40-60 oz.) generally means a denser, more durable product.

- Dtex: A measure of linear mass density, indicating the weight of the yarn in grams per 10,000 meters. A higher Dtex signifies a thicker, more robust fiber, contributing to longevity.

- Stitch Rate: The number of stitches per square meter. A high stitch rate creates a dense surface that supports the ball, preventing it from sinking and ensuring a true roll.

3. The Unseen Hero: The Sub-Base

The most critical aspect of any professional backyard putting green construction is the foundation. A properly engineered sub-base is non-negotiable for performance and durability. It typically consists of several compacted layers of crushed aggregate (like Class II road base), ensuring:

- Perfect Drainage: Prevents water from pooling on the surface, allowing for play even after heavy rain.

- Structural Stability: Creates a solid, smooth foundation that won't shift or develop undulations over time.

- Contour Design: Allows for the creation of custom breaks, slopes, and undulations that mimic a real course.

Mastering the Craft: The HoyarnGrass 6-Step Construction Process

Our commitment to excellence is reflected in our meticulous, ISO 9001-compliant construction process. Each step is executed with precision by certified installers to guarantee a world-class putting green.

Precision installation is key to a seamless and professional putting surface.

HoyarnGrass Premier Putting Green Turf: Technical Specifications

Our flagship product, the Artificial Grass for Construction Sites, is engineered for resilience and performance, making it the ideal choice for a professional-grade putting green that stands the test of time. It's not just for construction sites; its durability is its core feature, perfect for a high-performance backyard putting green construction.

| Parameter | Specification | Advantage |

|---|---|---|

| Product Name | Artificial Grass for Construction Sites (Putting Green Grade) | Engineered for extreme durability and professional performance. |

| Pile Height | 13mm (+/- 1mm) | Optimized for a true, consistent ball roll, mimicking bentgrass greens. |

| Dtex | 8800 | High-density yarn ensures exceptional resilience and a lifespan of 8-10 years. |

| Stitch Rate | 31,500 stitches/m² | Ultra-dense surface supports the golf ball, preventing sinking for a true roll. |

| Material | 100% PE Monofilament (C6 DOW Imported) | Superior softness, UV resistance, and player-friendly feel. Non-toxic and lead-free. |

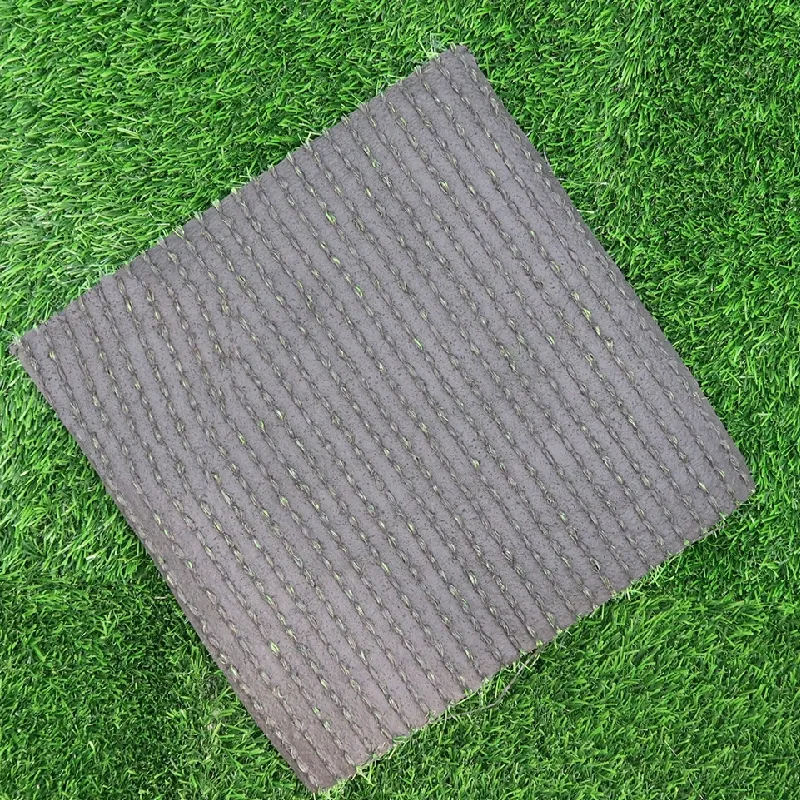

| Backing | PP Cloth + Net + SBR/PU Coating | Triple-layer backing provides dimensional stability and superior tuft lock. |

| UV Stability | Tested to >8000 hours (DIN 53387) | Guarantees colorfastness and fiber integrity against harsh sunlight. |

| Warranty | 8 Years | Backed by industry-leading quality assurance and material standards. |

| Certifications | ISO 9001, ISO 14001, CE, REACH | Independently verified for quality, safety, and environmental standards. |

Data-Driven Comparison: Why HoyarnGrass Excels

Making an informed decision requires a clear comparison. Here’s how HoyarnGrass's solution for artificial putting green construction stands against typical industry offerings.

| Feature | HoyarnGrass | Standard Competitor | Budget Option |

|---|---|---|---|

| Material Source | 100% C6 DOW Imported PE | Blended PE/PP | Recycled/Unspecified PE |

| Warranty Period | 8 Years | 5-7 Years | 1-3 Years |

| UV Resistance (Test Hours) | > 8000 Hours | ~ 5000 Hours | |

| Backing System | 3-Layer PU/SBR Coating | 2-Layer Latex | Single Layer Latex |

| Lead & Heavy Metal Free | Yes (REACH Certified) | Usually | Not Guaranteed |

| Stimp Rating Customization | Precise (9-12 range) | Limited Range | Non-adjustable |

Data visualization clearly demonstrates the quality advantage of premium turf materials.

75% Polyethylene (PE)

20% Polypropylene (PP)

5% Nylon

From Dream to Reality: Customization & Case Studies

Every golfer is unique, and so is every backyard. Our core philosophy is that artificial turf construction for putting greens should never be a one-size-fits-all solution. We offer extensive customization to create your perfect practice environment.

Your Green, Your Rules: Customization Options

- Shape and Size: From small, simple circles to large, free-flowing kidney shapes that integrate with your landscape.

- Stimp Speed: We can tune the green speed by adjusting the amount of sand infill, typically achieving a Stimp rating between 9 (local club speed) and 12 (tournament speed).

- Breaks and Undulations: Our expert base construction allows for the creation of subtle or challenging slopes and contours to test your putting skills.

- Hole Placement: Choose the number and location of cups for a variety of practice putts.

- Fringe & Chipping Areas: Add a taller fringe or even a dedicated chipping pad with a different turf style to practice your complete short game.

A custom-designed green offers both aesthetic beauty and unparalleled practice opportunities.

Application Showcase: Real-World Success Stories

Case Study 1: The Suburban Family's Recreational Hub

Client: The Miller Family, Austin, TX

Challenge: A sloped, underutilized section of their backyard that was difficult to mow. They wanted a fun, engaging feature for their children and for entertaining guests.

Solution: We designed and executed a 500 sq. ft. backyard putting green construction with three holes and gentle undulations. The green was set to a moderate Stimp speed of 9.5, making it enjoyable for all skill levels. We used our durable, soft PE turf, ensuring it was safe for kids.

Client Feedback: "The putting green has completely transformed our backyard. It's the first place the kids run to after school, and our weekend barbecues have a new centerpiece. The HoyarnGrass team was professional, and the quality is outstanding."

Case Study 2: The Competitive Golfer's Training Facility

Client: Mr. Chen, a low-handicap amateur, San Diego, CA

Challenge: Required a highly realistic practice surface to maintain and improve his short game. He needed a fast green with complex breaks to simulate tournament conditions.

Solution: We installed a 750 sq. ft. green focusing on performance. The sub-base was meticulously sculpted to create a double-breaking 15-foot putt. The green was tuned to a fast Stimp rating of 11.5. A 2-inch pile height fringe was added for practicing delicate chip shots.

Outcome: The client reported a measurable improvement in his putting statistics within three months. The project demonstrated how our technical approach to artificial putting green construction can meet the demands of even the most serious golfers.

Every project is a testament to our commitment to quality and client satisfaction.

Ready to Build Your Dream Green?

Experience the ultimate in-home golf. Partner with the experts in high-performance artificial turf. Contact us for a personalized consultation and quote.

Start Your Backyard Putting Green Construction ProjectProfessional FAQ: Your Questions Answered

The 'Stimp rating' or 'Stimp speed' is a measurement of how fast a golf ball rolls on a putting green, quantified using a device called a Stimpmeter. A higher number indicates a faster green. In artificial putting green construction, we primarily control this by:

1. Type of Turf: The density and style of the turf fibers provide a baseline speed.

2. Infill Amount: This is the key adjustment factor. Less sand infill allows the fibers to stand more upright, creating more resistance and a slower green. More infill weighs the fibers down, creating a smoother, faster surface. We can precisely tune the green to a client's desired speed, typically from 9 to 12.

Polyethylene (PE) is the modern standard for high-quality putting greens. Its fibers are softer, more resilient, and less abrasive, providing a more realistic feel that mimics natural bentgrass. It's excellent for receiving chip shots. Polypropylene (PP) is a stiffer, more durable fiber that creates a very fast, "billiard table" like surface. While very durable, it's often considered less realistic for all-around play and is sometimes used for fringe or specialized, very fast greens.

The sub-base is arguably the most critical component. A poorly constructed base will lead to a failed putting green, regardless of the turf quality. A proper sub-base, made of compacted aggregate, provides three essential functions: 1) **Unwavering Stability**, preventing dips, humps, or shifting over time; 2) **Superior Drainage**, ensuring the green is playable in all weather conditions; and 3) **The Canvas for Design**, allowing installers to create the permanent contours and breaks that make a green challenging and fun.

Dtex, or Decitex, is a unit of measurement for the linear mass density of a yarn, defined as the mass in grams per 10,000 meters of that yarn. In simple terms, it's a measure of the yarn's thickness and weight. A higher Dtex value (like the 8800 in our product) indicates a heavier, more substantial fiber. This translates directly to better durability, improved resilience (the ability to spring back), and a longer lifespan for the turf.

Maintenance is minimal compared to natural grass but essential for peak performance. We recommend:

• Regularly removing debris (leaves, twigs) with a leaf blower.

• Brushing the fibers occasionally with a stiff-bristled broom to keep them upright, especially in high-traffic areas.

• Checking and replenishing sand infill every couple of years if needed, though with our dense turf this is rare.

• Rinsing with water if it gets soiled. No mowing, watering, or fertilizing is ever needed.

Drainage is a two-part system. First, the artificial turf itself has perforation holes (typically every 4-6 inches) that allow water to pass directly through it. Second, and more importantly, the water then reaches the permeable sub-base. The compacted aggregate base is designed to hold and slowly dissipate water into the ground beneath, preventing any pooling on the surface. This is why professional backyard putting green construction is essential for all-weather playability.

Reputable artificial turf should come with independent, third-party certifications that attest to its quality and safety. Key ones include:

• ISO 9001: Guarantees the manufacturer follows strict quality management processes.

• ISO 14001: Shows commitment to environmental management.

• CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

• REACH or RoHS: Certifies that the product is free from harmful levels of lead, heavy metals, and other hazardous substances, ensuring it's safe for families and pets.

References and Further Reading:

- United States Golf Association (USGA). "How to Build a Putting Green." Provides standards on green construction principles, applicable to both natural and artificial surfaces. USGA Green Section.

- Journal of Turfgrass and Sport Surface Science. Research on performance characteristics of artificial turf, including ball roll and surface hardness. Wiley Online Library.

- GCSAA Forum. "Discussion on Artificial vs. Natural Green Maintenance Costs." An industry forum where golf course superintendents discuss the pros and cons of different turf types. GCSAA Resource Center.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories