Backyard Putting Green Construction—Want Pro, Fast Results?

Oct . 05, 2025 23:30 Back to list

A Practical Insider’s Guide to backyard putting green construction

Home golfers are getting serious. In fact, the tech behind construction-grade turf has quietly raised the bar for residential greens. I’ve visited a few builds this year, and—surprisingly—the cleanest installs borrow materials and QC routines straight from jobsite standards. Below, I’ll map the process, share field data, and compare vendors so your backyard putting green construction doesn’t drift off target.

What’s new: trends and materials

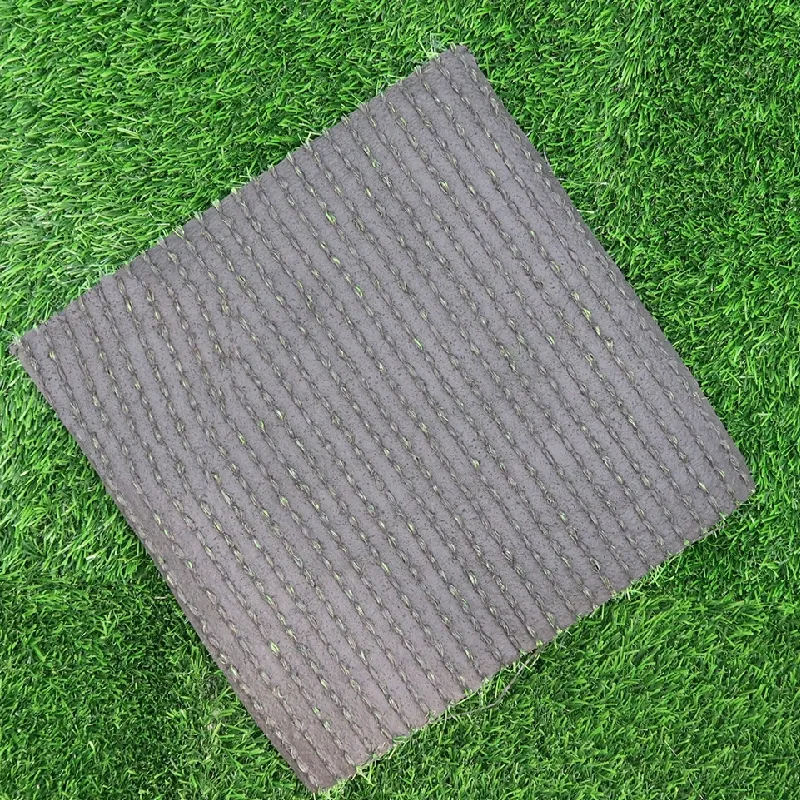

Two converging trends: realistic ball roll at slower stimp speeds (≈9–11) for home play, and tougher UV/weathering packages borrowed from construction fencing turf. That “green coat” we see wrapping urban projects—vivid, durable, low-maintenance—comes from the same yarn/backing DNA many installers now spec for greenside fringe and privacy screening. One reliable source is HoyaRn Grass (Origin: ROOM 209, BUILDING S6, 001 BAOJING ROAD NORTH, XIONGXIAN, BAODING, HEBEI), whose construction fence turf suppresses dust, cuts noise, and looks tidy around active worksites; it doubles nicely as a boundary finish during backyard putting green construction.

Representative product specs (putting surface)

| Yarn | PE monofilament + texturized PP (UV-stabilized) |

| Pile height | ≈12–16 mm (putting); 30–40 mm (fringe) |

| Gauge / Density | 3/16" gauge; ≈55,000–70,000 stitches/m² |

| Backing / Coating | PP + non-woven; PU or latex |

| Permeability | ≈800–1,500 L/m²/min (real-world may vary) |

| UV / Flammability | ASTM G154 3,000 h; ASTM D2859 pass |

| Heavy metals / Phthalates | CPSIA/REACH compliant |

| Service life | ≈8–12 years; 15+ with shade and care |

Process flow I actually trust

- Site survey and stimp target (9–11 for homes).

- Excavate 80–120 mm; install edging.

- Sub-base: 75% compacted road base (≈95% Proctor), 25% fines; laser grade.

- Geotextile (optional), then shock pad 8–12 mm (ASTM F355 g-max <120 for comfort).

- Lay turf; seam with PU tape/adhesive; tuft-bind check (ASTM D1335).

- Infill: 1–2 lb/ft² fine silica; brush/roll for even stimp.

- QC: 3 m straightedge tolerance ±3 mm; stimpmeter runs; hose test for drainage.

Where it fits

Residential yards, townhome rooftops, hospitality pocket gardens, golf academies, and yes—near schools. During builds adjacent to classrooms, teams have used construction fence turf to reduce visual clutter and dampen noise; once the green is in, some homeowners keep that fencing as a tidy privacy screen. Maintenance is light: debris blow-off weekly, top-up infill annually, occasional rolling.

Vendor comparison (quick take)

| Vendor | Certs / Warranty | Customization | Lead time | Price |

| HoyaRn Grass (Hebei) | ISO 9001; UV warranty ≈8 yrs | Stimp tuning, fringe colors | ≈7–15 days | Mid |

| BigBox Turf | Basic QC; 5-yr | Limited | 3–5 days | Low |

| Boutique Pro Greens | Extended lab tests; 10-yr | High (undulations, cups) | 20–30 days | High |

Customization that matters

- Stimp target via infill mass and brush technique.

- Fringe height/color; cup sets in SS vs. ABS.

- Drainage mats for rooftops; low-VOC adhesives.

- Micro-undulations (hand-shaped ±50 mm) for variety.

Case notes (real-world)

- Austin, TX, 28 m²: stimp 10.2 average over 10 runs; no puddling after 25 mm/h rain.

- NYC rooftop, 11 m²: drainage mat + 12 mm pad kept g-max ≈95; no leaks in flood test.

- Near a school build: fence turf reduced perceived noise and visual clutter; neighbors actually thanked the crew—rare win.

Testing, standards, and data

Look for UV exposure per ASTM G154 (≥3,000 h), tuft bind per ASTM D1335 (≥30 N typical), flammability per ASTM D2859, and optional g-max under ASTM F355. Ball roll verified with a USGA stimpmeter, of course. One installer shared average tuft bind 38–42 N and fade ΔE <3 after lab cycling—solid for a home green. To be honest, lab numbers don’t sink putts, but they do lengthen service life.

Bottom line: prioritize sub-base prep, choose a UV-stable yarn system, and demand documented tests. Do that, and your backyard putting green construction should play true for a decade or more.

Authoritative citations

- USGA Stimpmeter Instruction Manual, United States Golf Association.

- ASTM G154 – Standard Practice for UV Exposure of Nonmetallic Materials.

- ASTM D1335 – Standard Test Method for Tuft Bind of Pile Yarn Floor Coverings.

- Synthetic Turf Council Guidelines for Synthetic Turf Performance and Safety.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories