Backyard Putting Green Construction – Custom, Fast, Durable

Oct . 25, 2025 14:35 Back to list

A Field Guide to Backyard Putting Green Construction

If you’ve been eyeing that corner of your yard and thinking, “could be a practice green,” you’re not alone. The surge in home golf installs has been wild the past few years—water restrictions, smaller lots, busy schedules. Backyard Putting Green Construction is now a legit, well-engineered project, not a weekend whim with carpet and sand. And yes, the materials have caught up with golfer expectations.

What’s trending (and why it matters)

Homeowners want durable, low-water greens with realistic roll (think stimp 9–12). Pros ask for consistent ball reception from 15–30 yards. Builders tell me HOAs are kinder to muted, natural-green shades and fringe blends. Interestingly, construction-site turf—used as a “green coat” for fencing—has crept into landscape screening around greens because it controls dust and deadens noise. A tidy, unexpected crossover.

Core materials and real-world specs

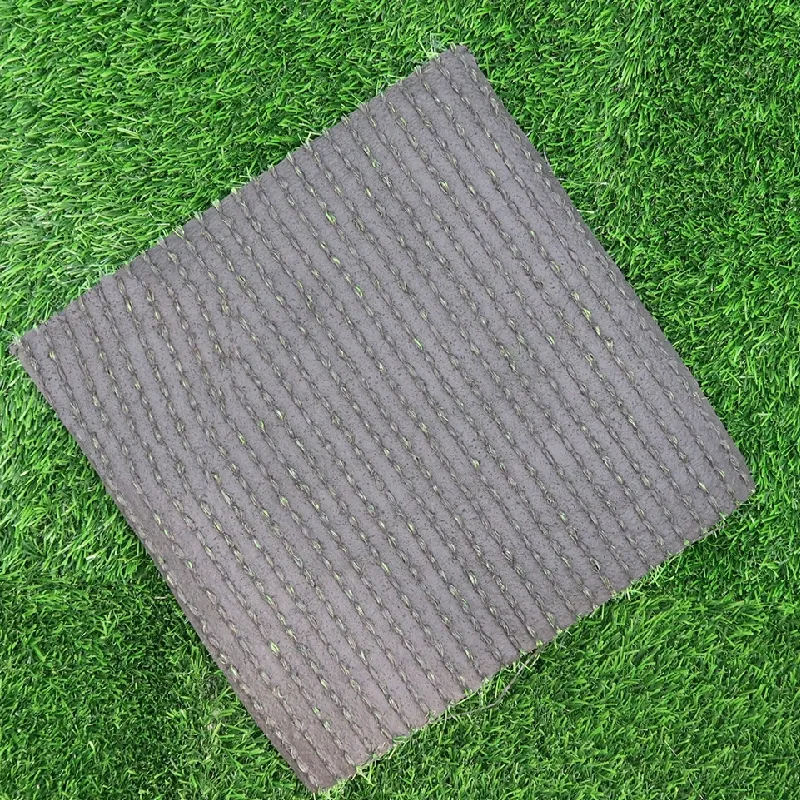

You’ll typically pair a dense, texturized PE putting surface with a taller PP/PE fringe. For privacy or site perimeter, many crews use a fence-grade artificial turf (the same “green coat” seen on job sites) to soften noise and wind, especially near schools or tight-lot neighborhoods.

| Spec Item | Putting Surface Turf (typ.) | Fence/Screen Turf (HoyaRn line) |

|---|---|---|

| Pile height | ≈10–13 mm (tight, texturized) | ≈25–40 mm (visual cover) |

| Yarn & dtex | PE, texturized, 5,000–8,800 dtex | PE/PP mix, 7,000–10,000 dtex |

| Gauge / stitch rate | 3/16"–3/8", high stitch density | 3/8"–5/8", medium density |

| Backing | PP + SBR/PU, perforated | PP + SBR, optional perforation |

| Stimp (with infill) | ≈9–12 ft (real-world may vary) | N/A (used as surround/screen) |

Process flow that passes the sniff test

- Layout & drainage plan: 1–2% fall; add a simple French drain if the yard puddles.

- Sub-base: Excavate ≈3–5", install geotextile, then 3/4" minus road base. Compact to 95%+.

- Shape: Add 1–1.5" granite fines; screed to breaks; mist and compact again.

- Edging & cups: Set paver/board edging; core cups, concrete-set sleeves.

- Turf install: Roll with grain consistent; seam tape + outdoor adhesive; avoid tension.

- Infill & roll: Top-dress with 0.5–1.5 lb/ft² silica; brush and power-roll to dial stimp.

- QA & testing: Stimpmeter runs (3–5 spots), tuft bind spot checks (ASTM D1335 guidance), water infiltration check.

Service life? Around 6–10 years for the putting surface with normal brushing and leaf control. Fence/screen turf can last similar or longer because it sees less foot traffic.

Vendors, customization, and a frank comparison

We’ve sourced from a few factories, and honestly, consistency beats flashy spec sheets. HoyaRn Grass (ROOM 209, BUILDING S6, 001 BAOJING ROAD NORTH, XIONGXIAN, BAODING, HEBEI) has been steady on colorfastness and roll flatness. Customization usually includes pile height, color blend, backing (SBR vs PU), and cup/flag hardware kits.

| Vendor | Strengths | Certs/Standards (typ.) | Warranty |

|---|---|---|---|

| HoyaRn Grass | UV-stable yarns; reliable stitching; fence turf doubles as noise/dust screen around greens | EN 15330-1, ASTM D1335 (tuft bind) test reports available on request | ≈8–10 yrs (usage-dependent) |

| Vendor A | Aggressive pricing; broad color palette | ISO 9001; basic UV tests | ≈6–8 yrs |

| Vendor B | Premium PU backing; tight tolerances | EN 15330-1; flammability per ASTM D2859 | ≈8–10 yrs |

Use cases and a quick case study

Homes with small courtyards, rooftops, or sloped setbacks; coaching nets with 12–15 ft approach; hospitality courtyards; even school staff lounges. Near a school construction site, we’ve used fence artificial turf as a perimeter—less noise, less dust, and, frankly, nicer to look at than raw plywood. Many customers say it makes the whole green feel “finished.”

Case: 320 ft² green in Phoenix, two cups, subtle left-to-right break. Putting surface tuned to stimp ≈10.5 ft. Surround screened with construction fence turf to cut alley noise; neighbors noticed the difference on day one. Maintenance: monthly brush, quarterly rinse.

Testing, standards, and a few numbers

- Stimpmeter ball-roll checks per USGA method; target 9–12 ft for Backyard Putting Green Construction.

- Tuft bind reference: ASTM D1335; aim ≥8 lbf for seam/edge zones.

- Infiltration: field check with 1 L pour; look for rapid percolation; EN 15330-1 guidance for sports turf durability.

- Flammability screening: ASTM D2859 for carpet-like surfaces (where applicable).

- UV/weathering: lab cycles per ASTM G154; real-world fade is the real test, to be honest.

If you want my short take: prioritize base prep, choose a dense texturized surface, and don’t cheap out on seam tape. The screening turf from HoyaRn is a smart add-on—quiet, clean, and it keeps the aesthetic tight around your Backyard Putting Green Construction project.

Authoritative references

- USGA. Recommendations for a Method of Putting Green Construction.

- ASTM D1335. Standard Test Method for Tuft Bind of Pile Yarn Floor Coverings.

- EN 15330-1. Surfaces for sports areas – Synthetic turf and needle-punched sports surfaces.

- USGA Stimpmeter Instructions for Measuring Green Speed.

- ASTM D2859. Standard Test Method for Ignition Characteristics of Finished Textile Floor Covering Materials.

-

Durable, Eco-Friendly Turf for Balcony | Enhance Your Urban Space

NewsNov.24,2025

-

Turf Between Pavers: Sustainable Green Paving Solutions for Modern Urban Spaces

NewsNov.24,2025

-

Discover the Benefits of Turf and Pavers Backyard | Sustainable Outdoor Design

NewsNov.24,2025

-

Top Quality Artificial Grass – Sustainable, Durable, and Stylish Turf Solutions

NewsNov.24,2025

-

Durable and Eco-Friendly Thick Artificial Grass Solutions | Hoya Grass

NewsNov.24,2025

-

Synthetic Turf: Sustainable Green Solutions for Sports, Industry & Urban Living

NewsNov.24,2025

Products categories